Learn more about Global Thermoforming

COVID-19 Manufacturing Initiatives

MENUMENU

- Our Company

- Gallery

- Services

- Industries

- Industries

- Thermoforming Industries

- Aerospace Thermoforming

- Agricultural Thermoforming

- Appliance Thermoforming

- Automotive Thermoforming

- Bath Showers Thermoforming

- Consumer Products Thermoforming

- HVAC Thermoforming

- Lawn & Garden Thermoforming

- Marine Thermoforming

- Medical Thermoforming

- Packaging Thermoforming

- Pool & Spa Thermoforming

- Recreational Vehicle Thermoforming

- Semiconductor Thermoforming

- Technology Thermoforming

- Window & Siding Thermoforming

- News

Semiconductor Thermoforming

Global Thermoforming delivers custom thermoformed plastic covers and enclosures engineered specifically for the semiconductor industry. From tight tolerances to cleanroom compatibility, our solutions keep your sensitive components safe, without compromising design flexibility or throughput.

Speed

We build our own thermoforming tools, thermoforming machines and extrude our own material, which means we can design and develop faster, fix production problems faster, and ensure you meet your deadlines.

Customization

We provide a broad array of plastic manufacturing capabilities. Whether your part calls for design, post-production machining, finishing, tooling manufacture, assembly or thermoformed packaging, we can handle all your needs on-site. We’ll make all the components!

Quality

Quality is the most important attribute of our vacuum forming company. We take great pride in delivering the best quality in the thermoforming industry. We are constantly striving to improve.

Customer Experience

Once your product is delivered, we will be by your side until it is fully integrated with your manufacturing processes. If complications occur, we are available within 24 hours to get it right and have your systems up and running.

Rapid Prototyping. Rapid Production.

Advanced Plastic Cover Solutions for Semiconductors.

Thermoforming for the semiconductor industry demands precision, reliability, and on-time delivery. Here at Global Thermoforming, we know that there’s no room for error. Whether you need static-dissipative housings, molded shielding covers, or transparent inspection windows, our team architects designs to your precise requirements. With ISO-certified processes and close-tolerance trimming, we deliver flawless, contamination-free parts. We do tooling, forming, trimming, finishing, and assembly under one roof — minimizing risk, lead times, and cost.

Have an upcoming project?

On-time Delivery

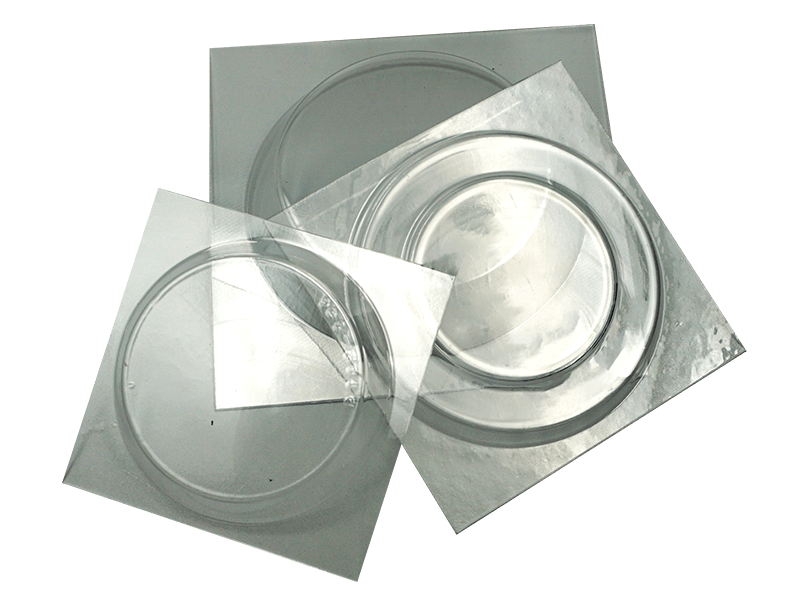

Thermoformed Semiconductor Custom Enclosures

Our experience with the semiconductor industry allows us to deliver on schedule. We work with specialty plastics suited for semiconductor environments (e.g. ESD-safe, flame retardant, chemical resistant) with our in-house engineering team, which saves valuable time in the thermoforming process. From prototype runs to high-volume production, our thermoforming lines and automation adapt to your throughput needs. Our engineers collaborate at all stages — design feedback, rapid prototyping, quality control, post-delivery support — ensuring seamless integration into your assembly lines.

What We Offer

Semiconductor Thermoforming

At Global Thermoforming (GTF), we design and manufacture specialized protective containers tailored to the semiconductor industry. Our precision-engineered solutions ensure safe handling, storage, and transport of your most sensitive equipment.

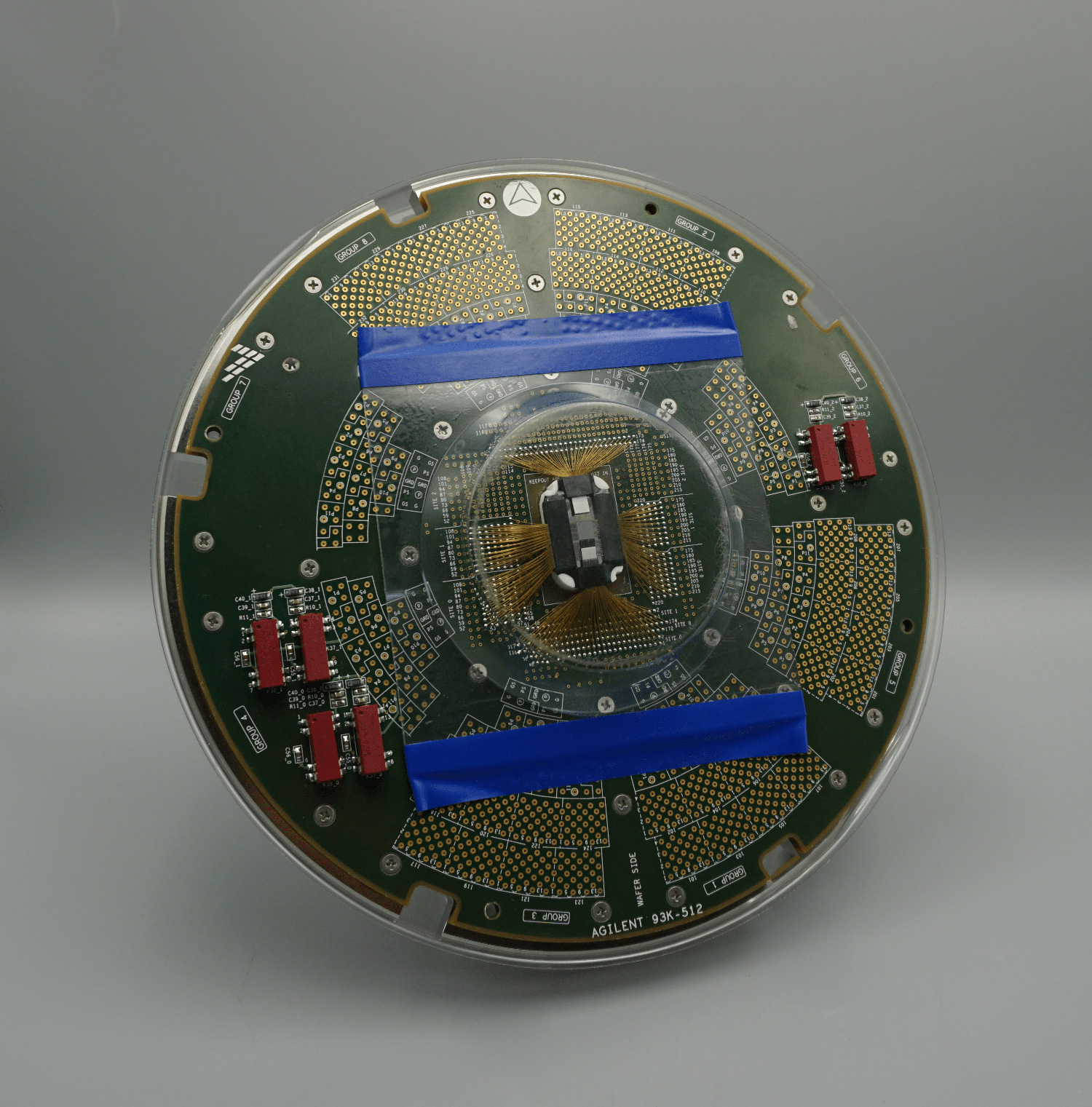

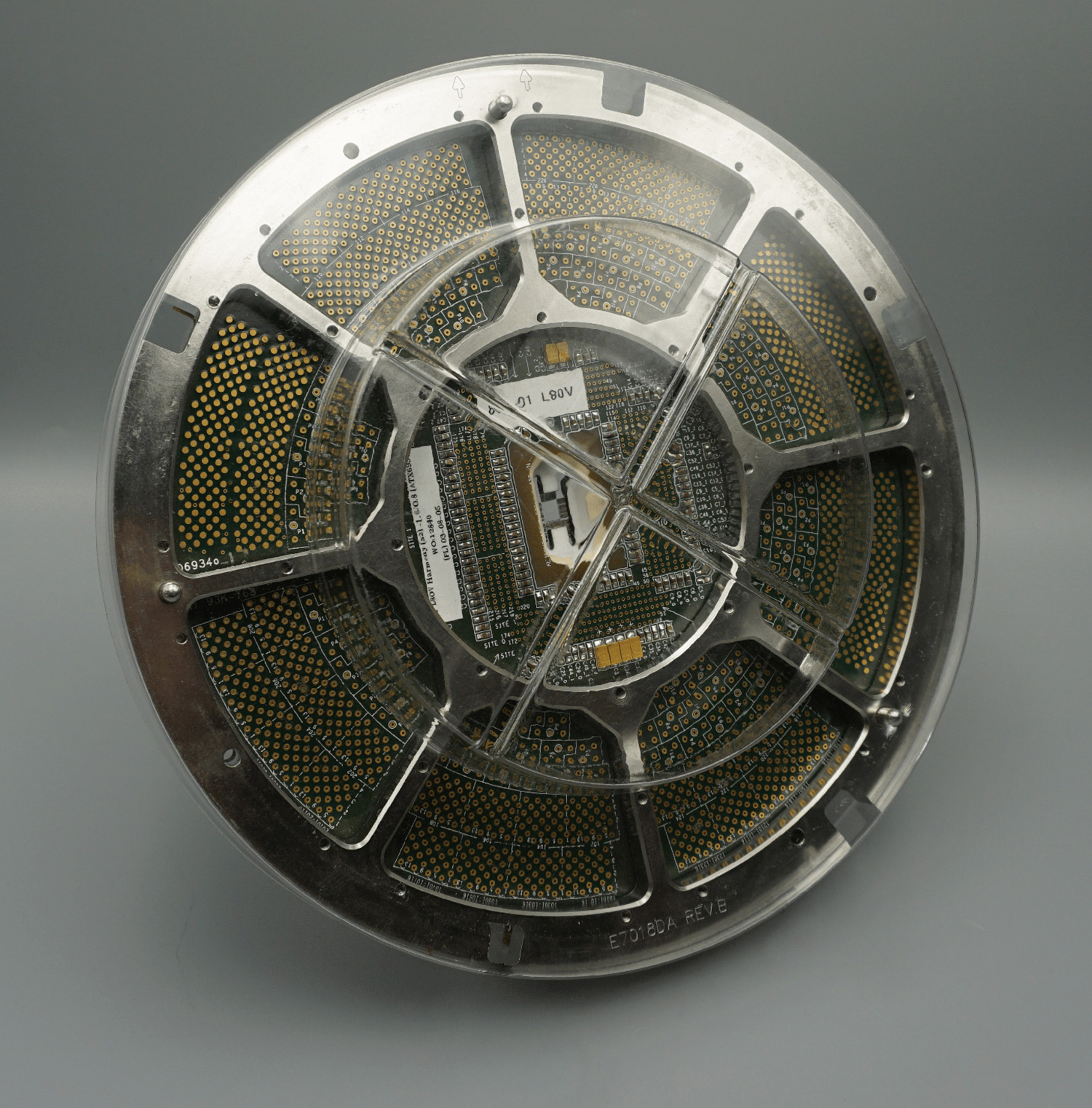

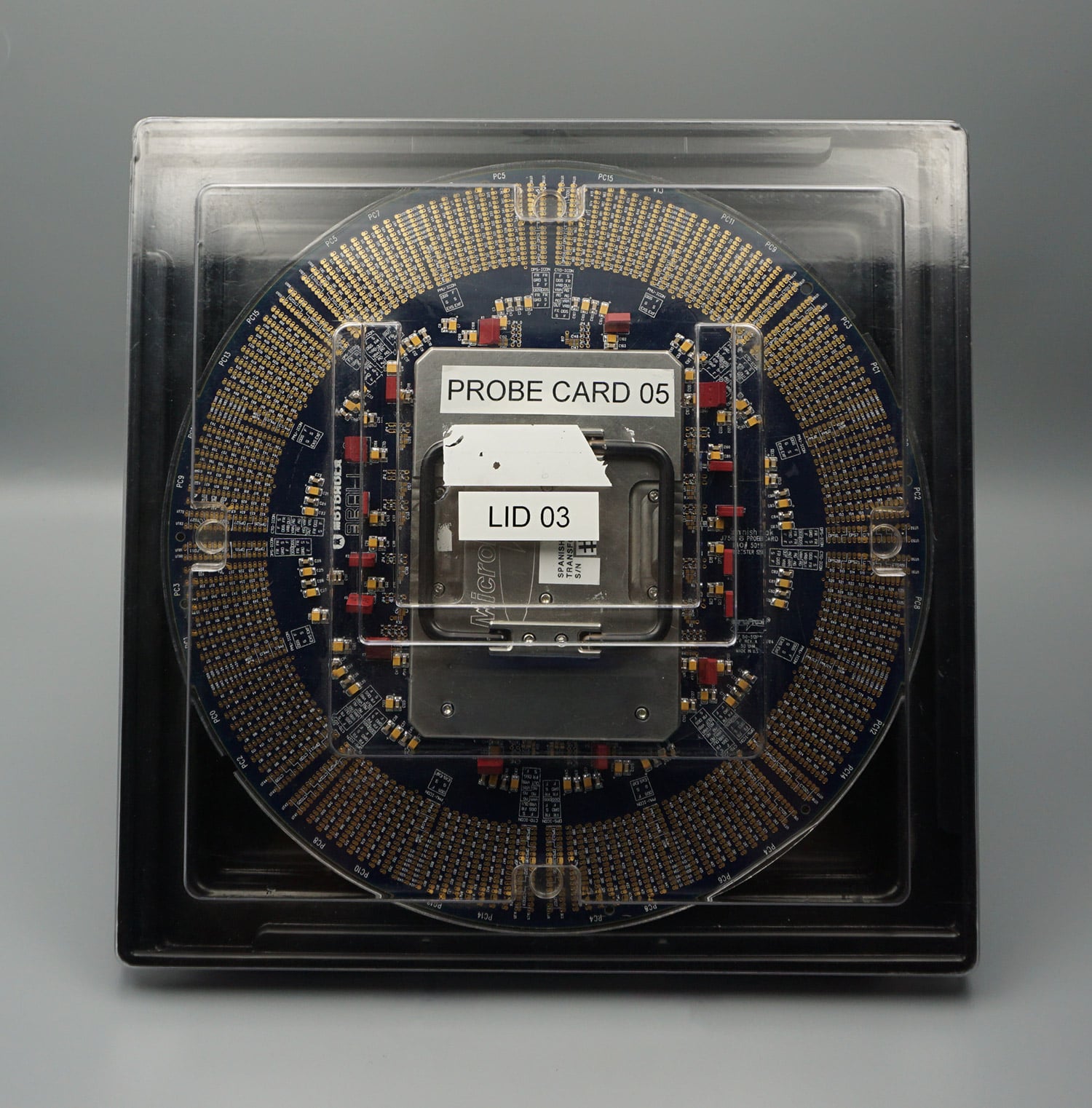

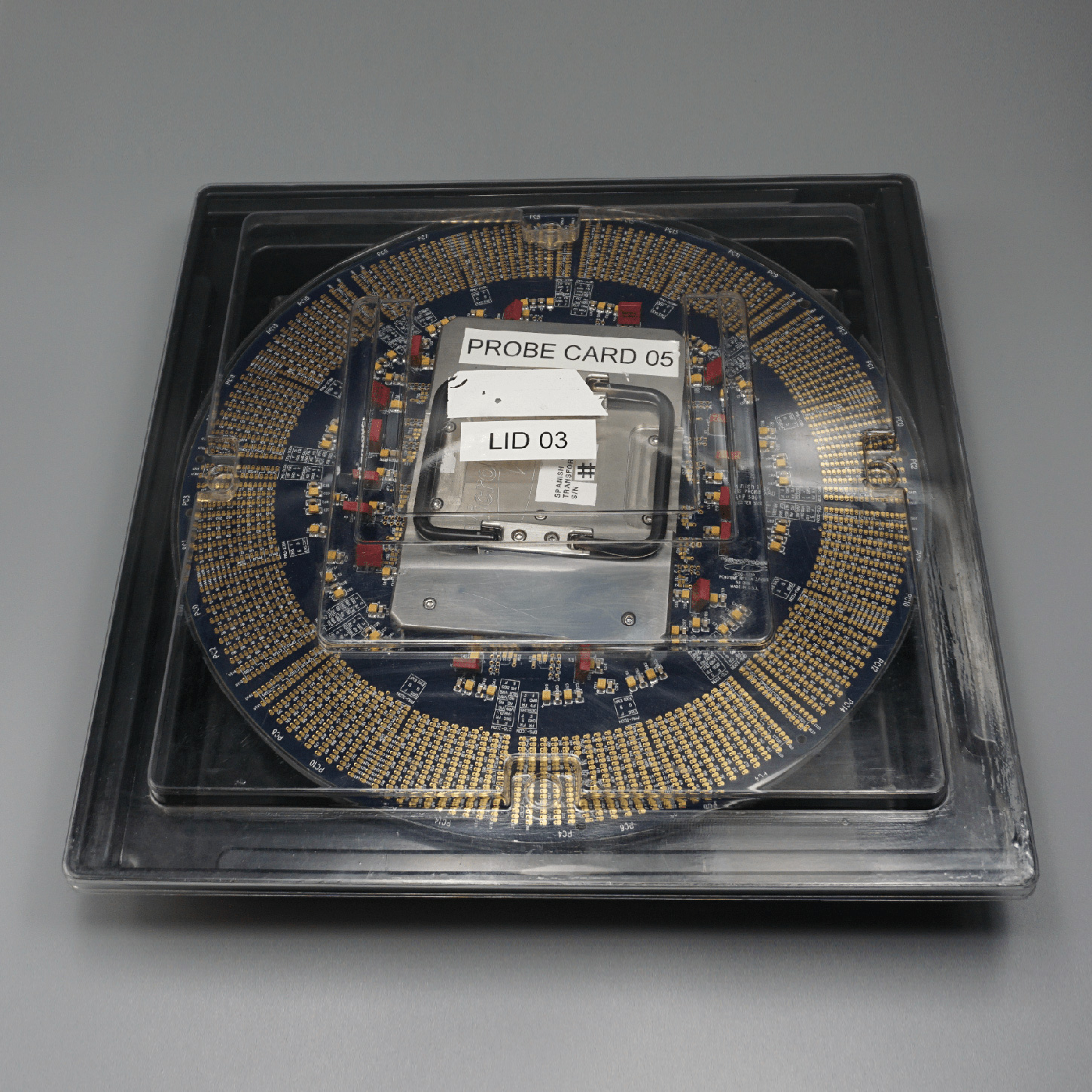

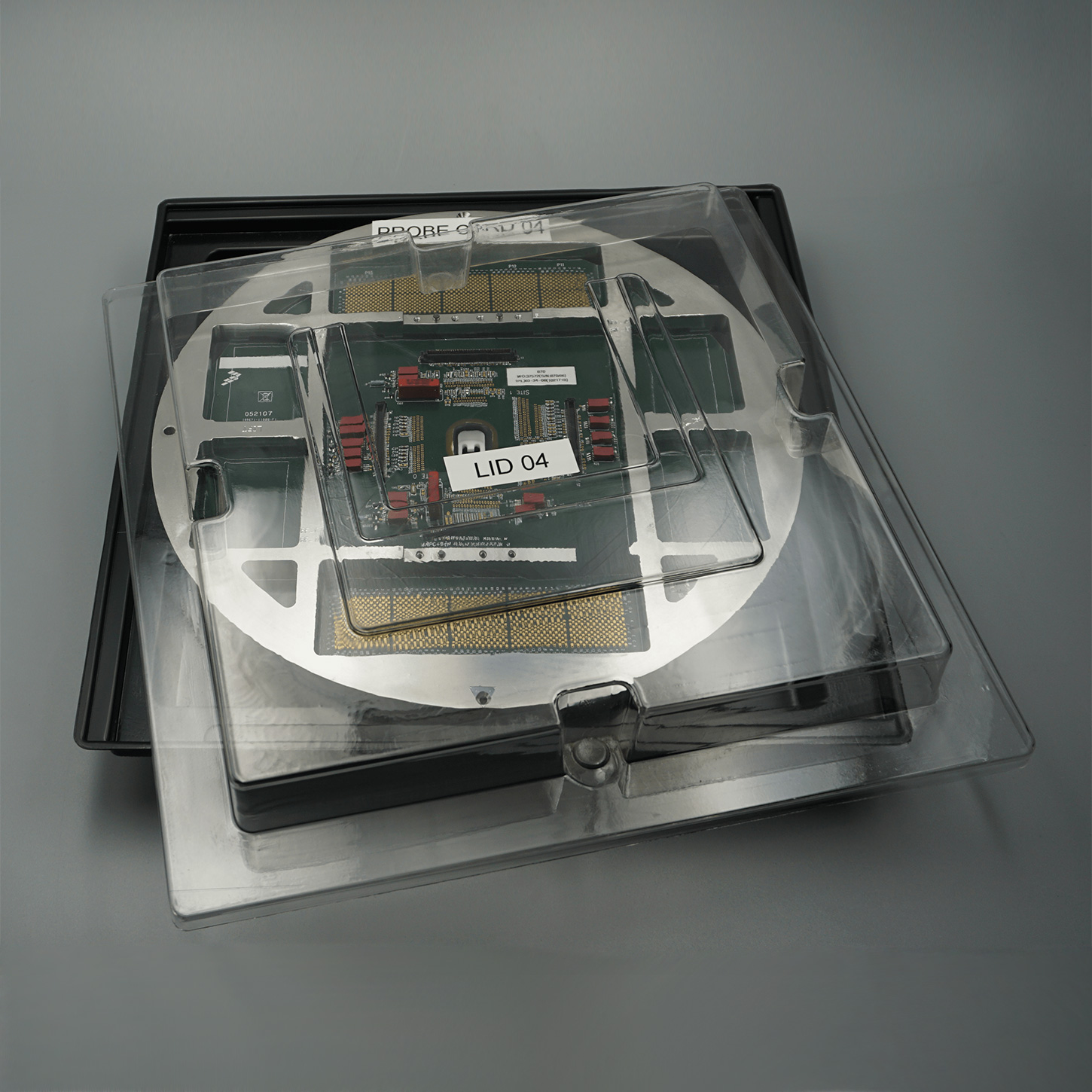

PC – Probe Card Container

The Probe Card Container (PC) is designed to provide maximum protection for delicate probe cards during transport and storage.

Durable Design: Thermoformed from high-impact plastics to withstand handling and stacking.

Precision Fit: Custom cavities keep probe cards secure and stable.

Cleanroom Ready: Manufactured to meet industry cleanliness standards.

Ideal for safeguarding high-value probe cards against dust, static, and mechanical stress.

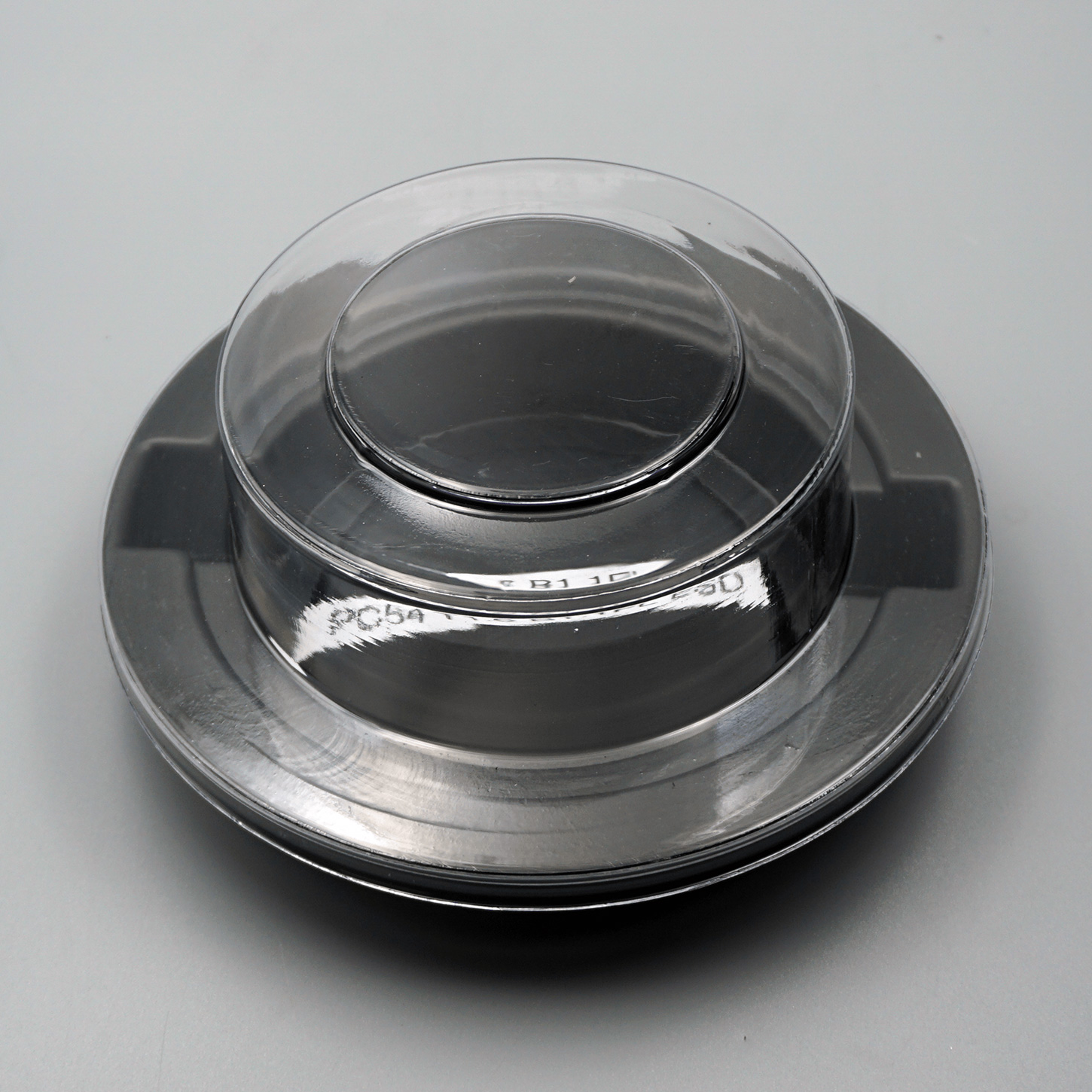

PTP – Probe Tip Protector

The Probe Tip Protector (PTP) offers specialized protection for the most critical and sensitive part of your probe card—the tips.

Micro-Precision Shielding: Prevents bending, breaking, or contamination of probe tips.

Compact & Secure: Lightweight design ensures easy use without adding bulk.

Custom Options: Available in multiple sizes and materials to fit different probe configurations.

A simple yet essential accessory to extend the lifespan and performance of probe cards.

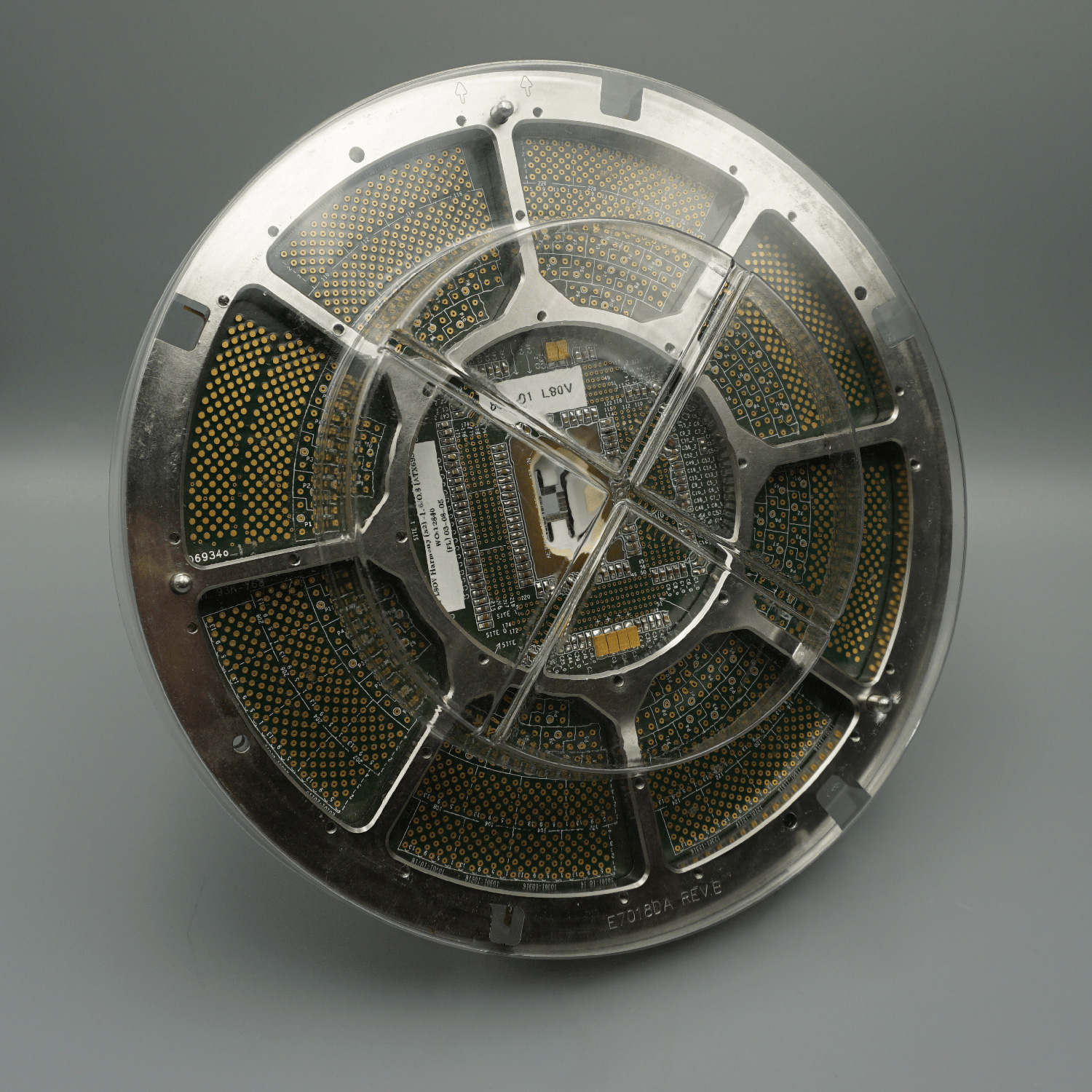

CC – Card Case

The Card Case (CC) provides a rugged, convenient solution for protecting and transporting a variety of cards used in semiconductor testing.

Versatile Use: Suitable for multiple card formats and interface boards.

Protective Build: Strong outer shell guards against impact, while soft internal support reduces vibration.

Portable Design: Lightweight and stackable for ease of handling.

Perfect for keeping your critical testing equipment safe and organized.

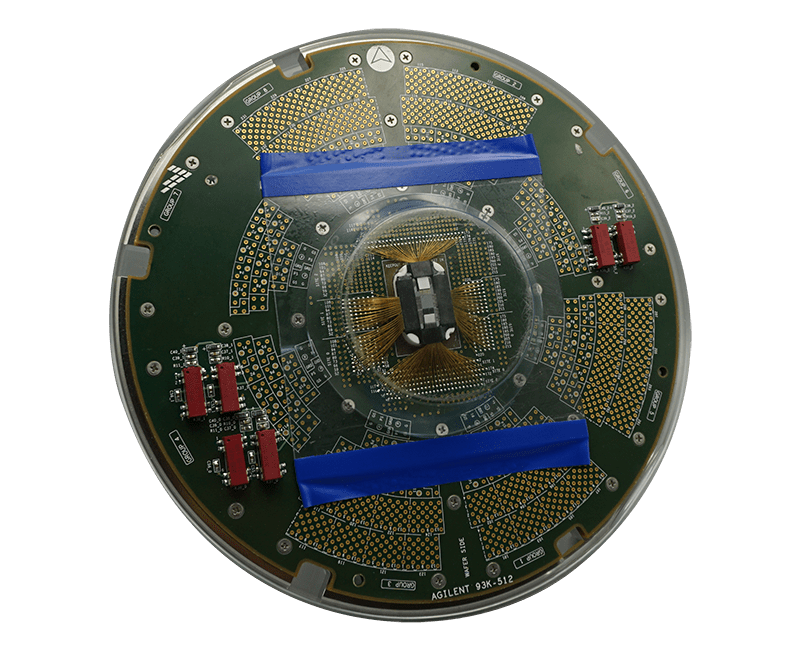

IBC – Interface Board Container

The Interface Board Container (IBC) is purpose-built for housing interface boards used in semiconductor probe stations.

Precision Fit Cavities: Ensures boards remain securely in place during transport.

Static Protection: Designed with ESD-safe materials to prevent electrostatic discharge.

Durable & Reusable: Built to last through repeated use in demanding environments.

The trusted solution for maintaining the integrity and functionality of interface boards.

CONTACT US

Semiconductor Thermoforming Inquiry

If you’re a part of the semiconductor industry and would like to learn more about our semiconductor thermoforming capabilities and how our team can help with challenging to design parts, faster turnaround times, and specialized materials experience, contact us today.

Copyright 2022 © Global Thermoforming | All Rights Reserved.

Site Designed and Developed by AVINTIV