Learn more about Global Thermoforming

COVID-19 Manufacturing Initiatives

MENUMENU

- Our Company

- Gallery

- Services

- Industries

- Industries

- Thermoforming Industries

- Aerospace Thermoforming

- Agricultural Thermoforming

- Appliance Thermoforming

- Automotive Thermoforming

- Bath Showers Thermoforming

- Consumer Products Thermoforming

- HVAC Thermoforming

- Lawn & Garden Thermoforming

- Marine Thermoforming

- Medical Thermoforming

- Packaging Thermoforming

- Pool & Spa Thermoforming

- Recreational Vehicle Thermoforming

- Technology Thermoforming

- Window & Siding Thermoforming

- News

Technology Thermoforming

Global Thermoforming ensures that our technology industry clients receive the best materials and tightest tolerances for products such as Autonomous Vehicle interior and exterior panels, 5G Cell Phone Tower Covers and more.

Speed

We build our own thermoforming tools, thermoforming machines and extrude our own material, which means we can design and develop faster, fix production problems faster, and ensure you meet your deadlines.

Customization

We provide a broad array of plastic manufacturing capabilities. Whether your part calls for design, post-production machining, finishing, tooling manufacture, assembly or thermoformed packaging, we can handle all your needs on-site. We’ll make all the components!

Quality

Quality is the most important attribute of our vacuum forming company. We take great pride in delivering the best quality in the thermoforming industry. We are constantly striving to improve.

Customer Experience

Once your product is delivered, we will be by your side until it is fully integrated with your manufacturing processes. If complications occur, we are available within 24 hours to get it right and have your systems up and running.

Rapid Prototyping. Rapid Production.

The Future Is Thermoformed

If you desire to create a more advanced technological future, it is necessary to work with materials and service providers that are leading their industry so that you can lead yours. Thermoforming for the technology industry demands precision, reliability, and on-time delivery. Self-driving cars are no longer the future, they are here now, and along with it advances in drone technology as well. Our team has been working on many of these types of projects and can help you prepare for the future using high-quality vacuum and pressure forming capabilities.

Have an upcoming project?

Quick Lead Times

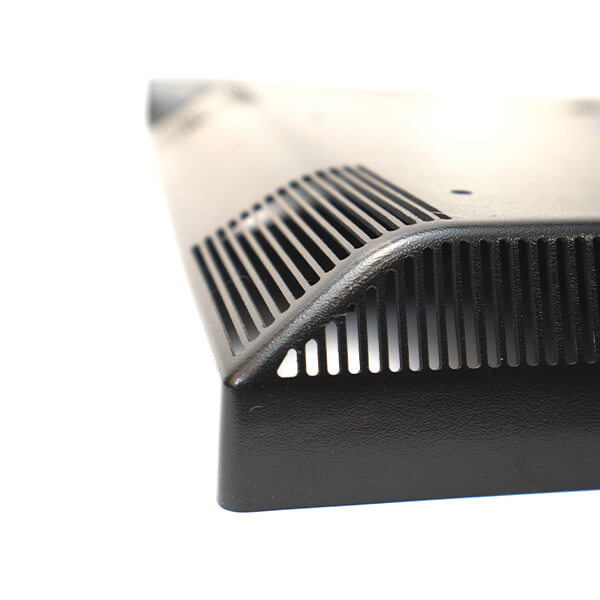

Thermoformed Technology Equipment

Our vacuum forming process is efficient and built into stages you can follow with ease. Our team and machines work on schedules designed to make a greater impact on the results you are looking for. With access to on-site product development and the capacity to handle components from design to assembly and trimming, we eliminate delays and ensure each panel, part or plastic cover is manufactured to the tightest tolerances.

What We Offer

Technology Thermoforming

The technology industry has grown swiftly over the past decade and the opportunities for advances in manufacturing have grown along with it. At Global Thermoforming, we have the advanced engineering capabilities to assist in producing a variety of equipment and parts to complete your designs. Materials such as Kydex, Royalite, and Boltaron meet requirements for fire resistance, durability, and safety, while our quality guidelines ensure that each item is manufactured with precision and on schedule.

Autonomous Vehicle – interior and exterior panels

The new era of transportation is here, and we have the right tools and machines to thermoform parts for all types of self-driving cars and buses. We specialize in door panels, interior panels, and more.

Military Drone Aircraft

Special operations are used for the production of various unmanned drone parts. Utilizing our 5-axis CNC routers, we are able to produce parts in the dimensions particular to your needs.

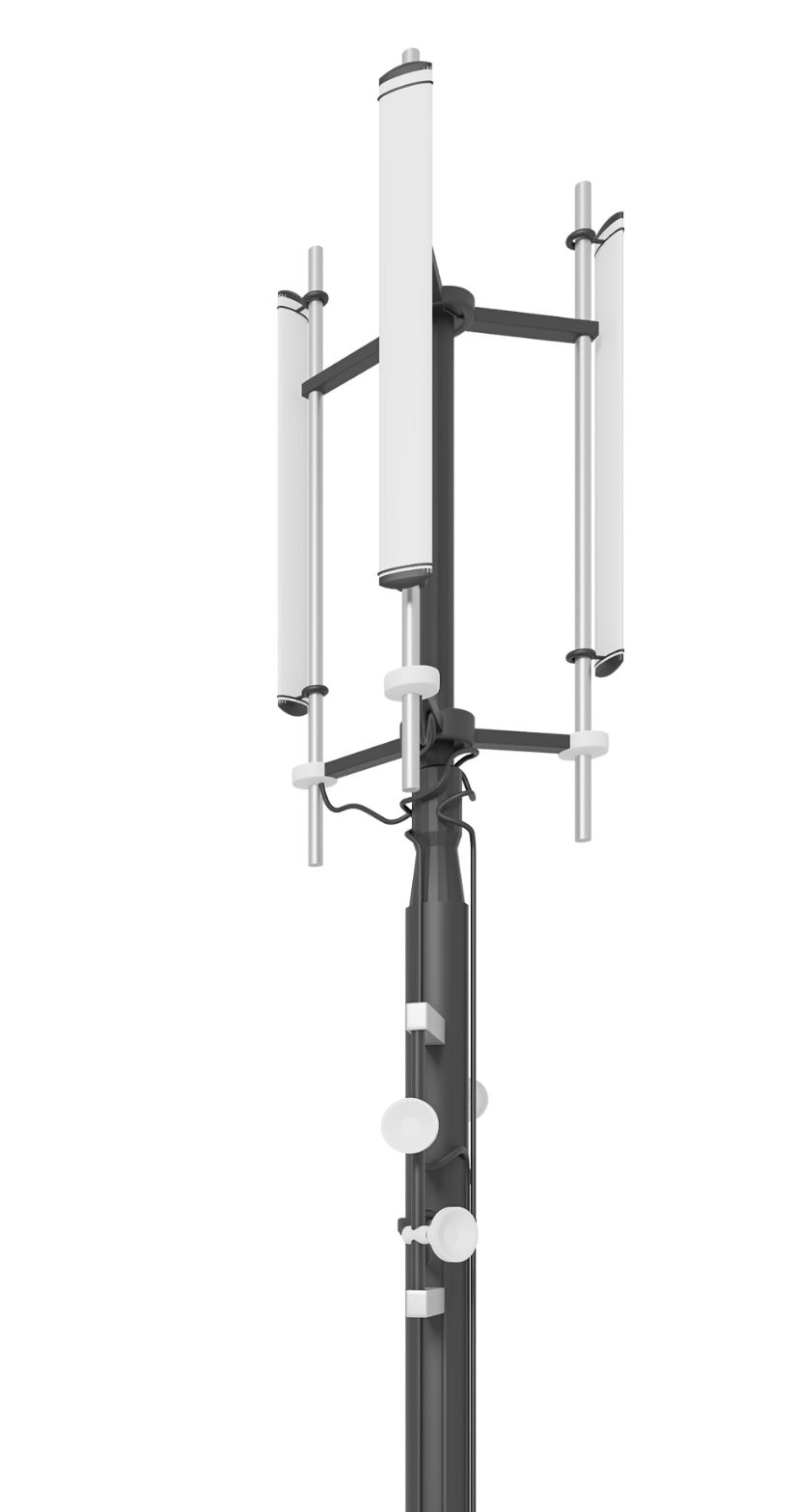

5G Cell Phone Tower Covers

Durability is key when it comes to producing cell phone tower covers. Our high-quality plastics are ideal for these parts, using thick-gauge thermoforming to get the job done swiftly and efficiently.

Key Cutting & Fob Copying Machines

For smaller machines, our capabilities are just as top tier as with anything else we do. We can craft any part with laser precision using durable plastics that will make for a product that can outlast all of the high-pressure from years of duplicating keys.

Packaging for Products

Thin-gauge thermoforming is another in-house specialty. When it comes to technology that is packaged in thin plastic casings, our machines are prepared to deliver high amounts of thin-gauged packaging for microchips and other technology accessories.

Custom Technology Thermoforming

Technology Thermoforming Gallery

CONTACT US

Technology Thermoforming Inquiry

If you’re a part of the technology industry and would like to learn more about our technology thermoforming capabilities and how our team can help with challenging to design parts, faster turnaround times, and specialized materials experience, contact us today.

Copyright 2022 © Global Thermoforming | All Rights Reserved.

Site Designed and Developed by AVINTIV