Learn more about Global Thermoforming

COVID-19 Manufacturing Initiatives

MENUMENU

- Our Company

- Gallery

- Services

- Industries

- Industries

- Thermoforming Industries

- Aerospace Thermoforming

- Agricultural Thermoforming

- Appliance Thermoforming

- Automotive Thermoforming

- Bath Showers Thermoforming

- Consumer Products Thermoforming

- HVAC Thermoforming

- Lawn & Garden Thermoforming

- Marine Thermoforming

- Medical Thermoforming

- Packaging Thermoforming

- Pool & Spa Thermoforming

- Recreational Vehicle Thermoforming

- Technology Thermoforming

- Window & Siding Thermoforming

- News

Secondary Operations

Custom Plastic Packaging

Global Thermoforming provides a variety of custom plastic packaging and secondary operations for thermoformed plastics, including CNC trimming, assembly, printing, painting, and drape forming.

CUSTOM PLASTIC PACKAGING | CNC TRIMMING | PRINTING | LABELING | PAINTING

Have an upcoming project?

Speed

We build our own thermoforming tools, thermoforming machines and extrude our own material, which means we can design and develop faster, fix production problems faster, and ensure you meet your deadlines.

Customization

We provide a broad array of plastic manufacturing capabilities. Whether your part calls for design, post-production machining, finishing, tooling manufacture, assembly or thermoformed packaging, we can handle all your needs on-site. We’ll make all the components!

Quality

Quality is the most important attribute of our vacuum forming company. We take great pride in delivering the best quality in the thermoforming industry. We are constantly striving to improve.

Customer Experience

Once your product is delivered, we will be by your side until it is fully integrated with your manufacturing processes. If complications occur, we are available within 24 hours to get it right and have your systems up and running.

SECONDARY OPERATIONS FOR CUSTOM PACKAGING

Finishing Your Custom Thermoformed Product

Because thermoforming begins with a relatively expensive finished sheet of plastic, minimizing scrap is an important step in containing costs. Though good part design can reduce trim, some trimming will be necessary.

We also offer other secondary options for finishing and finalizing your products.

CUSTOM PLASTIC PACKAGING

Secondary Options For Your Custom Product

At Global Thermoforming, we have in-house capabilities that allow you to customize all aspects of your thermoformed plastic product and your custom plastic packaging.

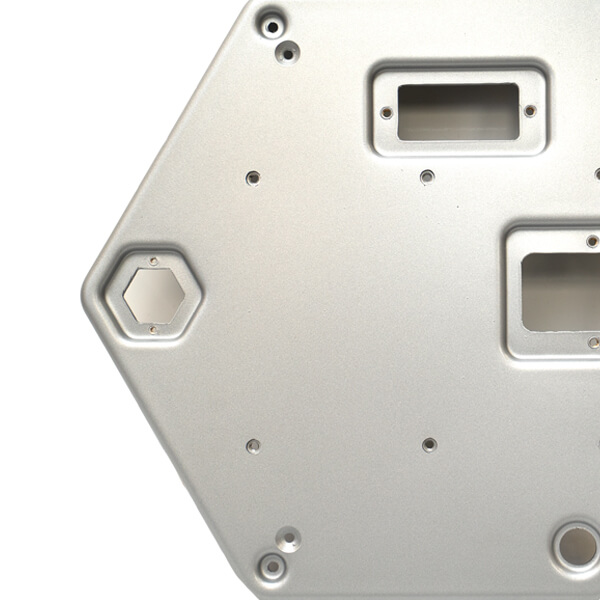

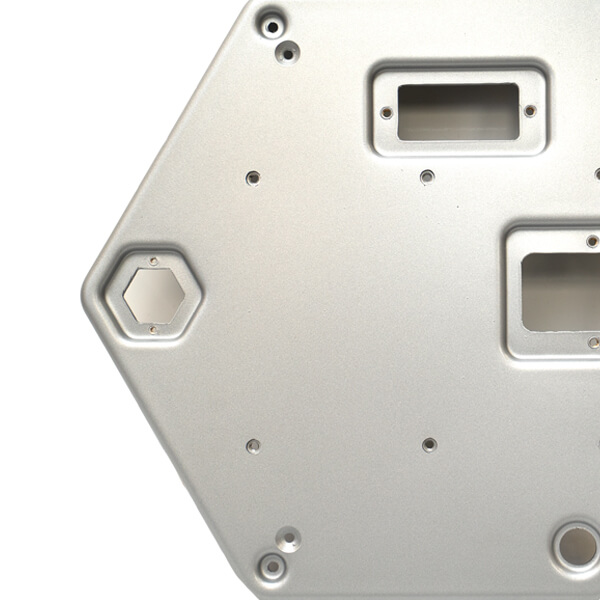

Trimming the Formed Part

It’s generally best to trim a part when it is warm. High-production parts are usually trimmed right in the mold.

Trimming should be done in a separate area designated just for that operation. Accurate positioning and holding of each part is important. Small, thin parts are usually held in place by surrounding locators. For parts with complex shapes, fixtures should be built to hold the part in place while it is being trimmed.

Fastening the Formed Parts

There are many ways to join thermoformed parts, including:

Mechanical fasteners, press and snap fits, solvent bonding, adhesive bonding, and ultrasonic welding.

Decorating & Printing the Formed Part

Part decorating usually begins with the mold design. The thermoforming process can transfer intricate mold details into the hot sheet. As a result, such highly defined details as lettering, logos, figures, and textures can be incorporated. Textured or embossed surfaces can give a plastic part a different appearance.

Printing

Printing is a process of marking a surface to apply decoration or information. Various techniques can be used to apply printing on thermoformed parts, including: Screen printing, Dyeing, Pad transfer, Diffusion, Flexography, Offset printing, and Laser printing

Labeling

To label thermoplastic parts, labeling machines are used. These include machines that perform:

Hot stamping, heat transfers, gummed labels, and decals.

Painting

Painting can add a special decorative effect or improve the part’s function. Some typical reasons for painting a part include:

- Improved chemical, abrasion, and weathering resistance.

- Color matching with adjacent parts or components.

- Electrical conductivity.

- Extra-high gloss or matte finish.

- Textured appearance where molded-in texture is not feasible.

- Covering of surface imperfections caused by processing.

- Many paint and primer systems are available that are compatible for use with thermoformed parts.

FINISHED PRODUCT

Secondary Operations

SECONDARY OPERATIONS

CNC Trimming and Finishing

SECONDARY OPERATIONS

Painting

SECONDARY OPERATIONS

Gibson Guitar Case Layering

SECONDARY OPERATIONS

CNC Trimming

Global Thermoforming, Inc is a leader in the thermoforming industry that provides quality thermoforming, custom plastic packaging, vacuum forming, clamshell, clamshell packaging, thin gauge thermoforming, thick gauge thermoforming, and a variety of other services to the entire United States. We have local thermoforming facilities in Tempe, AZ and Nashville, TN. Contact us today for all of your thermoforming needs.

Copyright 2022 © Global Thermoforming | All Rights Reserved.

Site Designed and Developed by AVINTIV