Learn more about Global Thermoforming

COVID-19 Manufacturing Initiatives

MENUMENU

- Our Company

- Gallery

- Services

- Industries

- Industries

- Thermoforming Industries

- Aerospace Thermoforming

- Agricultural Thermoforming

- Appliance Thermoforming

- Automotive Thermoforming

- Bath Showers Thermoforming

- Consumer Products Thermoforming

- HVAC Thermoforming

- Lawn & Garden Thermoforming

- Marine Thermoforming

- Medical Thermoforming

- Packaging Thermoforming

- Pool & Spa Thermoforming

- Recreational Vehicle Thermoforming

- Technology Thermoforming

- Window & Siding Thermoforming

- News

Appliance Thermoforming

Global Thermoforming ensures that our appliance industry clients receive the best materials and tightest tolerances for products such as refrigerator panels, air conditioner panels, microwave and oven accessories and components.

Speed

We build our own thermoforming tools, thermoforming machines and extrude our own material, which means we can design and develop faster, fix production problems faster, and ensure you meet your deadlines.

Customization

We provide a broad array of plastic manufacturing capabilities. Whether your part calls for design, post-production machining, finishing, tooling manufacture, assembly or thermoformed packaging, we can handle all your needs on-site. We’ll make all the components!

Quality

Quality is the most important attribute of our vacuum forming company. We take great pride in delivering the best quality in the thermoforming industry. We are constantly striving to improve.

Customer Experience

Once your product is delivered, we will be by your side until it is fully integrated with your manufacturing processes. If complications occur, we are available within 24 hours to get it right and have your systems up and running.

Custom Applications. Guaranteed Satisfaction.

Experience That Speaks For Itself

Thermoforming for the appliance industry requires thorough knowledge of the elements that these appliances will need to withstand. Not only that, every model or unit will have unique specifications that require exact precision when it comes to trimming materials and ensuring a proper fit. At Global Thermoforming, we have years of experience to guide you through the process. Our expert staff is ready to share their knowledge about which thermoforming plastics will work best for your project.

Have an upcoming project?

Expert Design Collaboration

Thermoformed Appliance Equipment

When you connect with Global Thermoforming for appliance thermoforming, you get access to a robust team of professionals who know how to take your visions and create components designed to handle the toughest of environments. We have an in-house engineering team, which saves valuable time in the thermoforming process. Our inline thermoforming machines are some of the best. Forming parts like inner refrigerator liners is a seamless process at Global, and with the latest capabilities in vacuum and pressure forming, we are able to produce parts with more inner cavities than before. Contact us today to find out why we are the right match for your appliance needs.

What We Offer

Appliance Thermoforming

The diversity of components needed in the appliance industry requires a variety of high-performance materials, ready to stand the test of performance. The materials used in our appliance thermoforming processes have a higher rate of durability, lasting up to 50% longer than previous generations of plastics. Below are some of the key appliance materials we are able to thermoform for you:

Refrigerator Panels and Components

Inner liners for refrigerators have a multitude of options when it comes to their design. With our thick-gauge thermoforming equipment, creating tough, industry-compliant parts is a guarantee. Our refrigerator and freezer door liners hold up to the standards expected with long-lasting daily use.

Microwave Panels and Components

Our microwave panels are also thoroughly tested for durability and withstanding high levels of heat. The plastics used for thermoforming microwave parts are as high-quality as they come, ensuring ease of maintenance for the end consumer.

Oven Panels and Components

Interior oven components, such as oven cabin side panels, need to be built to withstand the hottest temperatures. Certified with ISO 9001:2015, our facilities and machinery are tested for high-quality output, every time. Working with our design team will ensure the specific outlines of your oven panels are precisely formed so any oven trays slide in with a perfect fit.

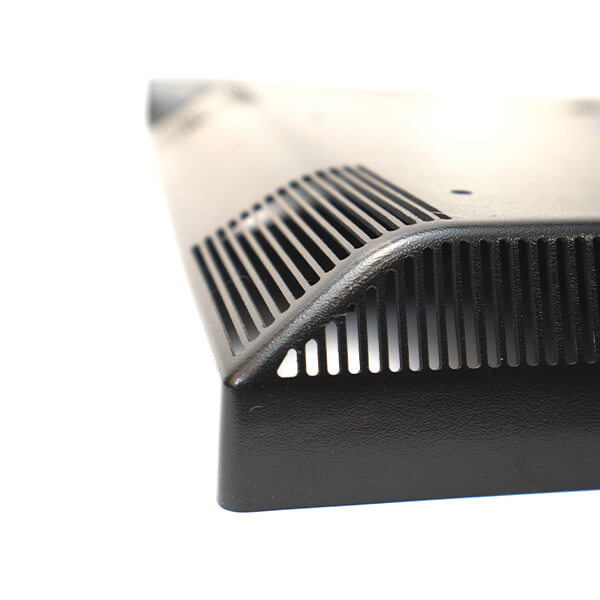

Air Conditioner Panels and Components

Our experience is vast when it comes to creating perfectly crafted air conditioner parts. Appliance clients will appreciate the attention to detail the Global team offers with the design of air conditioner covers. Built to withstand a variety of outdoor conditions, our plastics will ensure a long-lasting final product.

Heating Panels and Components

Thermoformed products for the appliance industry have a need for tight tolerances and experts who understand the nuances of manufacturing such components. Global Thermoforming ensures your heating panels will be delivered with high-quality design customization.

Custom Appliance Thermoforming

Appliance Thermoforming Gallery

CONTACT US

Appliance Thermoforming Inquiry

If you’re a part of the appliance industry and would like to learn more about our appliance thermoforming capabilities and how our team can help with challenging to design parts, faster turnaround times, and specialized materials experience, contact us today.

Copyright 2022 © Global Thermoforming | All Rights Reserved.

Site Designed and Developed by AVINTIV