Learn more about Global Thermoforming

COVID-19 Manufacturing Initiatives

MENUMENU

- Our Company

- Gallery

- Services

- Industries

- Industries

- Thermoforming Industries

- Aerospace Thermoforming

- Agricultural Thermoforming

- Appliance Thermoforming

- Automotive Thermoforming

- Bath Showers Thermoforming

- Consumer Products Thermoforming

- HVAC Thermoforming

- Lawn & Garden Thermoforming

- Marine Thermoforming

- Medical Thermoforming

- Packaging Thermoforming

- Pool & Spa Thermoforming

- Recreational Vehicle Thermoforming

- Technology Thermoforming

- Window & Siding Thermoforming

- News

Quality Vacuum Forming

Let Us Exceed Your Expectations

Global Thermoforming offers a full range of concept development to production services for small-run to high-volume vacuum forming projects. Recognized for our quality vacuum forming, close tolerance forming, and trimming capabilities, we fulfill your quality requirements in both thin gauge and heavy gauge materials at competitive pricing.

Have an upcoming project?

Speed

We build our own tools and vacuum forming machines and extrude our own material, which means we can design and develop faster, fix production problems faster, and ensure you meet your deadlines.

Customization

At Global Thermoforming, we provide a broad array of manufacturing capabilities. Whether your part calls for design, post-production machining, finishing, tooling manufacture, assembly or packaging, we can handle all your needs on-site. We’ll make all the components!

Quality

Quality thermoforming is Global Thermoforming’s most important attribute. We take pride in delivering the best quality in our industry. We are constantly striving to improve. At Global Thermoforming, quality is everyone’s job.

Customer Experience

Once your product is delivered, we will be by your side until it is fully integrated with your manufacturing processes. If complications occur, we are available within 24 hours to get it right and have your systems up and running.

OVER 30 YEARS OF MANUFACTURING EXPERIENCE

From Design To Production

We provide a broad array of thermoforming and plastic manufacturing capabilities. Whether your part calls for design, post-production machining, finishing, tooling manufacture, assembly or packaging, we can handle all your needs on-site. We’ll make all of the components!

Design and Prototyping

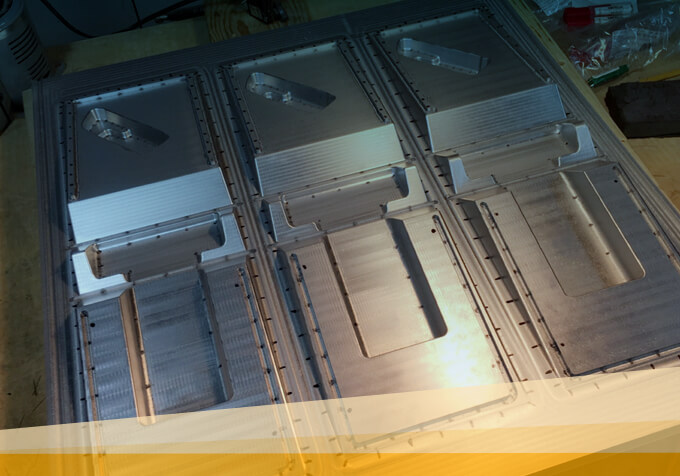

Custom Tooling

Thermoforming

CNC Trimming

Secondary Services

Measurement and Quality Control

Packaging

Shipping

APPLICATION OPPORTUNITIES

The ability to produce large parts with thin walls in a variety of shapes has led to the use of thermoforming in many diverse applications, for many industries including:

OUR THERMOFORMING PROCESS

Quality and Consistency

Quality is Global Thermoforming’s most important attribute. We take pride in delivering the best quality thermoforming, vacuum forming, and thermoformed packaging in our industry. We are constantly striving to improve. At Global Thermoforming, quality is everyone’s job!

ONGOING SUPPORT

Customer Experience

At Global Thermoforming, we stay involved through the entire process. Once your thermoformed product is delivered, we will be by your side until it is fully integrated with your manufacturing processes. If complications occur, we are available within 24 hours to get it right and have your systems up and running. Our goal is to deliver products with speed, quality, and customer-centric experiences at the forefront. Let us exceed your expectations.

Initial Meeting or Call

Welcome! We’d like to hear all about your products and the vision you have in mind. We pride ourselves in having a great sales team that will help you throughout the process of your entire project. Our sales team works closely with our production team to make sure we hit our lead times and produce the highest quality parts in our field.

01

Production – High or Low Volume

We have state of the art thermoforming machines and equipment! From high speed “inline” thermoforming machines along with 3-station rotary machines that give us high volume capability. Our smaller shuttle thermoforming machines allow for lower volume projects.

04

Design and Engineering

Design & Engineering are very important in thermoforming! We take your vision and try to improve it by reducing costs, improving manufacturability, and adding value to your end customer. We have over 50+ years of combined experience on our engineering team.

02

Lead Times

Because accurate and timely information is vital in any business strategy, we make your priorities are put first! Typical production lead times in our industry can vary from 4 – 10 weeks pending on the particular project.

05

Prototyping

Rapid Prototyping! As soon as your design is completed and approved, we can get you prototypes in as little as 2 days! Most companies we’ve worked with over the years have found prototyping is vital in the process to launch a new product. We offer a variety of mold options, all depending on your particular project.

03

Final Product

The duration from prototype approval to final product delivery varies anywhere from 2-14 weeks, dependent on the scope of work and complexity of the part. No solution is out of reach; your finished product will be beautiful, high quality, and completed with speed and efficiency.

06

VACUUM FORMING CAPABILITIES

Custom Tooling and Thermoforming

Thermoforming is the most cost effective and quality solution for your manufacturing needs.

Ryan Nelson

Director of Design

“As a custom product design & manufacturing company in the wireless industry, we are continually pushing the envelope on what engineered composites can do. Larson only partners with vendors that can provide a value added service beyond their core capabilities. Global is our go-to vendor for thermoformed engineered composites as they have time and again proven their commitment to the quality of not only their scope of work, but the entire project as a whole. This is a team that actively participates in the design and manufacturing process to ensure the end product meets our very high expectations. This team knows what they are doing and are willing to be creative and push the boundaries, simple as that… this is why we trust them as a partner.”

Gina Butler

Founder/Owner

“I have done business with them for years and I fully trust their capabilities,work ethic and quality of product. They are an amazing company and are like family. ”

Global Thermoforming, Inc is a leader in the thermoforming industry that provides quality vacuum forming, clamshell, clamshell packaging, thin gauge thermoforming, thick gauge thermoforming, and a variety of other services to the entire United States. We have local thermoforming facilities in Tempe, AZ and Nashville, TN. Contact us today for all of your thermoforming needs.

Copyright 2022 © Global Thermoforming | All Rights Reserved.

Site Designed and Developed by AVINTIV