Learn more about Global Thermoforming

COVID-19 Manufacturing Initiatives

MENUMENU

- Our Company

- Gallery

- Services

- Industries

- Industries

- Thermoforming Industries

- Aerospace Thermoforming

- Agricultural Thermoforming

- Appliance Thermoforming

- Automotive Thermoforming

- Bath Showers Thermoforming

- Consumer Products Thermoforming

- HVAC Thermoforming

- Lawn & Garden Thermoforming

- Marine Thermoforming

- Medical Thermoforming

- Packaging Thermoforming

- Pool & Spa Thermoforming

- Recreational Vehicle Thermoforming

- Technology Thermoforming

- Window & Siding Thermoforming

- News

Plastic Thermoforming Manufacturer

As a top plastic thermoforming manufacturer, we provide some of the highest quality services for thermoforming plastics. Our thermoforming process, SPEC, and other quality programs mean our parts live up to your standards. In fact, we are a preferred supplier to Motorola and Snap-on Tools among many other top companies in the United States. Quality and consistency is our most important attribute.

Have an upcoming project?

Speed

We build our own thermoforming tools, thermoforming machines and extrude our own material, which means we can design and develop faster, fix production problems faster, and ensure you meet your deadlines.

Customization

We provide a broad array of plastic manufacturing capabilities. Whether your part calls for design, post-production machining, finishing, tooling manufacture, assembly or thermoformed packaging, we can handle all your needs on-site. We’ll make all the components!

Quality

Quality is the most important attribute of our vacuum forming company. We take great pride in delivering the best quality in the thermoforming industry. We are constantly striving to improve.

Customer Experience

Once your product is delivered, we will be by your side until it is fully integrated with your manufacturing processes. If complications occur, we are available within 24 hours to get it right and have your systems up and running.

PRODUCE HIGHER QUALITY PARTS

What is Thermoforming?

Thermoforming is a manufacturing process that a plastic manufacturer uses to heat up a plastic sheet to a pliable forming temperature, then formed to a specific shape in a tool/mold, and trimmed to create a usable product. The sheet, or “film” when referring to thinner gauges and certain material types, is heated in an oven to a high-enough temperature that permits it to be stretched into or onto a mold and cooled to a finished shape. Its simplified version is called vacuum forming.

Thermoforming differs from injection molding, blow molding, rotational molding and other forms of processing plastics. Thin-gauge thermoforming is primarily the manufacture of disposable cups, containers, lids, trays, blisters, clamshells, and other products for the food, medical, and general retail industries. Thick-gauge thermoforming includes parts as diverse as vehicle door and dash panels, refrigerator liners, utility vehicle beds, and plastic pallets.

QUALITY PLASTIC MANUFACTURING

What can we do for you?

Design and Prototyping

Custom Tooling

Thermoforming

CNC Trimming

Secondary Services

Measurement and Quality Control

Packaging

Shipping

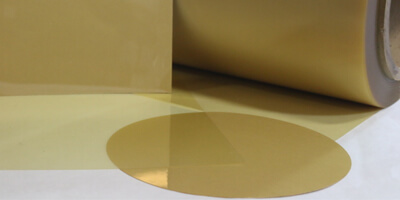

THERMOFORMING PLASTICS

Thick Gauge Thermoforming

CLIENTS: BRIDGESTONE | GIBSON GUITARS | NISSAN | BOEING

Global Thermoforming specializes in thick gauge thermoforming with capabilities of forming up to 1” thick. We’ve formed all types of thermoforming plastics in our industry and have helped our customers form their ideas into solutions they never dreamed of.

THERMOFORMING PLASTICS

Thin Gauge Thermoforming

CLIENTS: GIGI’S CUPCAKES | SCOTTS MIRACLE GRO | GOO GOO CLUSTERS

Thin-gauge thermoforming is plastic manufacturing of disposable cups, containers, lids, trays, blisters, clamshells, and other products for the food, medical, and general retail industries.

THERMOFORMING PLASTICS

Secondary Operations

IN-HOUSE CAPABILITIES: CNC TRIMMING | PRINTING | LABELING | PAINTING

As a top plastic thermoforming manufacturer, Global Thermoforming provides a variety of custom plastic packaging and secondary operations, including CNC trimming, assembly, printing, painting, and drape forming.

APPLICATION OPPORTUNITIES

The ability to produce large parts with thin walls in a variety of shapes has led to the use of thermoforming in many diverse applications, for many industries including:

MATERIALS AND TOLERANCES

Thermoforming Materials We Use

Thermoforming and plastic manufacturing allows you the option to use a wide variety of materials. Each material has its own unique capabilities, advantages and tolerances. This information will help you begin the process of deciding which material is right for your next project.

THIN AND THICK MATERIAL

Tolerances

Over time, accepted tolerances become industry standard. But if you need better-than-standard tolerances, just let us know. We’d be happy to help. As mold and part dimensions increase in size, so must tolerances.

Thick Gauge Thermoforming Material Tolerances

Activity Tolerance | Guideline |

|---|---|

| Formed Measurements | +/- .020” | Additional .001 Per Inch Beyond 12” |

| Drilled Hole Diameters | +/- .005” | Holes Equal or Lesser than 1” |

| Drilled Hole Diameters | +/- .010” | Holes Greater Than 1” to 5” |

| Slots | +/- .010” | Slots Equal or Lesser Than 1”in Any Direction |

| Slots | +/- .020” | Slots Greater Than 1” |

| Assembly Tolerances | +/- .010” | Additional .005 Per Inch Beyond 12” |

Thin Gauge Thermoforming Material Tolerances

Activity Tolerance | Guideline |

|---|---|

Formed Measurements | +/- .010” | Additional .001 Per Inch Beyond 12” |

Die Cut Dimensions | +/- .010” | +/- .010” | Additional .001 Per Inch Beyond 12” |

Global Thermoforming, Inc is a leader in the thermoforming plastics industry that provides thermoforming, vacuum forming, clamshell, clamshell packaging, thin gauge thermoforming, thick gauge thermoforming, and a variety of other services to the entire United States. We have local thermoforming facilities in Tempe, AZ and Nashville, TN. Contact us today for all of your thermoforming needs.

Copyright 2022 © Global Thermoforming | All Rights Reserved.

Site Designed and Developed by AVINTIV