Learn more about Global Thermoforming

COVID-19 Manufacturing Initiatives

MENUMENU

- Our Company

- Gallery

- Services

- Industries

- Industries

- Thermoforming Industries

- Aerospace Thermoforming

- Agricultural Thermoforming

- Appliance Thermoforming

- Automotive Thermoforming

- Bath Showers Thermoforming

- Consumer Products Thermoforming

- HVAC Thermoforming

- Lawn & Garden Thermoforming

- Marine Thermoforming

- Medical Thermoforming

- Packaging Thermoforming

- Pool & Spa Thermoforming

- Recreational Vehicle Thermoforming

- Technology Thermoforming

- Window & Siding Thermoforming

- News

Aerospace Thermoforming

Global Thermoforming ensures that our aerospace industry clients receive the best materials and tightest tolerances for products such as overhead storage bins, machined accessories, and components.

Speed

We build our own thermoforming tools, thermoforming machines and extrude our own material, which means we can design and develop faster, fix production problems faster, and ensure you meet your deadlines.

Customization

We provide a broad array of plastic manufacturing capabilities. Whether your part calls for design, post-production machining, finishing, tooling manufacture, assembly or thermoformed packaging, we can handle all your needs on-site. We’ll make all the components!

Quality

Quality is the most important attribute of our vacuum forming company. We take great pride in delivering the best quality in the thermoforming industry. We are constantly striving to improve.

Customer Experience

Once your product is delivered, we will be by your side until it is fully integrated with your manufacturing processes. If complications occur, we are available within 24 hours to get it right and have your systems up and running.

Rapid Prototyping. Rapid Production.

Best Materials.

Tightest Tolerances.

Thermoforming for the aerospace industry demands precision, reliability, and on-time delivery. Here at Global Thermoforming, we know that there’s no room for error. Our clients receive products with the best materials in the plastics industry, such as Kydex, Royalite, and Boltaron. We provide the tightest tolerances within the industry – (+/- 0.001” – 0.010”). Our vacuum and pressure forming capabilities along with our tool making produce the finest parts, tools and secondary fixtures available, with the tightest assembly tolerances.

Have an upcoming project?

On-time Delivery

Thermoformed Aerospace Equipment

Our experience with the aerospace industry and clients such as Raytheon, BAE Systems, Collins Aerospace, and B/E Aerospace allows us to deliver on schedule. We build our own tools and secondary fixtures, as well as have an in-house engineering team, which saves valuable time in the thermoforming process. With access to on-site product development and the capacity to handle components from design to assembly and shopping, we eliminate delays and ensure each item is manufactured to the tightest tolerances.

What We Offer

Aerospace Thermoforming

The diversity of components needed in the aerospace industry requires experience and the capability to deal with a range of high-performance materials. Global Thermoforming works with demanding specifications to produce aerospace-grade plastic components for cabin interiors and more. Materials such as Kydex, Royalite, and Boltaron meet requirements for fire resistance, durability, and safety, while our quality guidelines ensure that each item is manufactured with precision and on schedule.

Overhead Storage Bins

Overhead storage bins are manufactured through our thick-gauge thermoforming equipment, creating tough, industry-compliant areas for passenger items. Our airport luggage totes handle the stresses of transporting luggage with ease.

Cup Holders

Our precision formed cup holders are an essential part of air travel and are manufactured to your exact specifications. Our holders utilize strong plastics that are both easy to sanitize and practical.

Arm Rests

Aircraft interior components such as our armrests require durability and surfaces that are easy to maintain and clean. Our thick-gauge manufacturing capabilities deliver, providing clients with comfortable, high-performance products. With our experience in the specialized materials required in the industry, we can supply items faster and more efficiently.

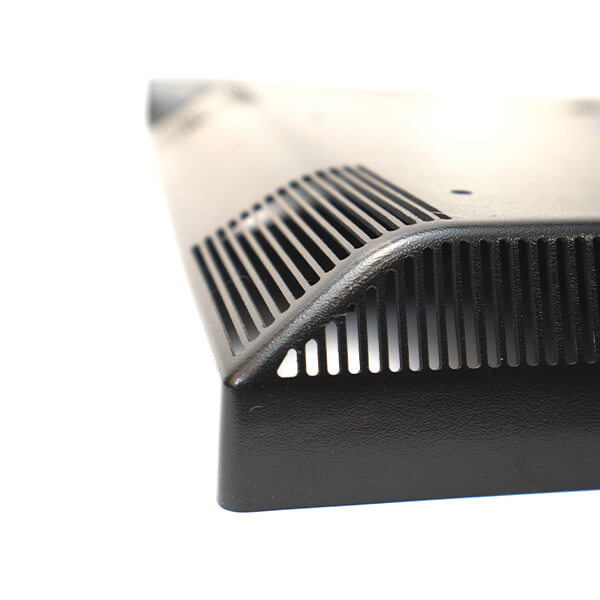

Machined Accessories and Components

We supply the custom machined components and accessories that are a frequent requirement for aerospace clients. Aircraft interiors utilize a vast range of these items, such as ventilation ducts, wall and ceiling panels, and storage areas.

Lighting Components and Fixtures

Thermoformed products for the aerospace industry have exacting material specifications, a need for tight tolerances, and require manufacturing expertise in working with the special plastics used in aviation-grade components. Global Thermoforming is at the forefront of delivering high-quality lighting lenses and covers, fixtures, and other products used for call lights, directional signs, overhead cabin illumination, and more. We offer in-house prototyping and complete customization capabilities.

Custom Aerospace Thermoforming

Aerospace Thermoforming Gallery

CONTACT US

Aerospace Thermoforming Inquiry

If you’re a part of the aerospace industry and would like to learn more about our aerospace thermoforming capabilities and how our team can help with challenging to design parts, faster turnaround times, and specialized materials experience, contact us today.

Copyright 2022 © Global Thermoforming | All Rights Reserved.

Site Designed and Developed by AVINTIV