Learn more about Global Thermoforming

COVID-19 Manufacturing Initiatives

MENUMENU

- Our Company

- Gallery

- Services

- Industries

- Industries

- Thermoforming Industries

- Aerospace Thermoforming

- Agricultural Thermoforming

- Appliance Thermoforming

- Automotive Thermoforming

- Bath Showers Thermoforming

- Consumer Products Thermoforming

- HVAC Thermoforming

- Lawn & Garden Thermoforming

- Marine Thermoforming

- Medical Thermoforming

- Packaging Thermoforming

- Pool & Spa Thermoforming

- Recreational Vehicle Thermoforming

- Technology Thermoforming

- Window & Siding Thermoforming

- News

Automotive Thermoforming

Global Thermoforming is a leader in supporting the automotive industry with our superior automotive thermoforming. We’re ISO 9001 Certified with IATF16949 Certification, using the best materials and the tightest tolerances to create items such as door panels, instrument panels, and consoles.

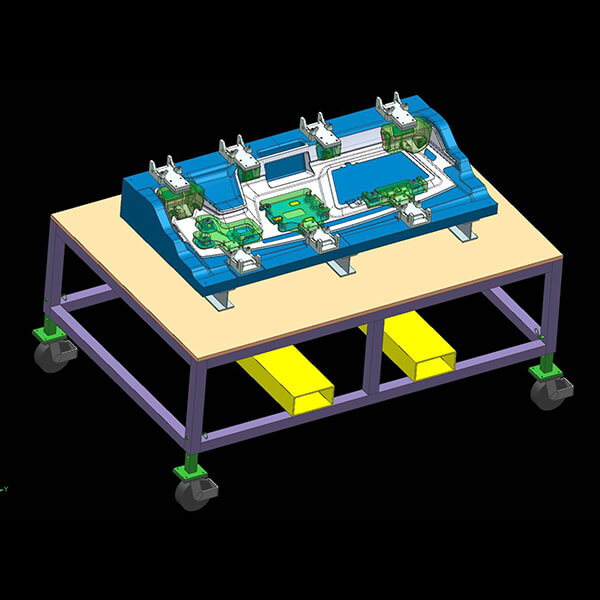

Speed

We build our own thermoforming tools, thermoforming machines and extrude our own material, which means we can design and develop faster, fix production problems faster, and ensure you meet your deadlines.

Customization

We provide a broad array of plastic manufacturing capabilities. Whether your part calls for design, post-production machining, finishing, tooling manufacture, assembly or thermoformed packaging, we can handle all your needs on-site. We’ll make all the components!

Quality

Quality is the most important attribute of our vacuum forming company. We take great pride in delivering the best quality in the thermoforming industry. We are constantly striving to improve.

Customer Experience

Once your product is delivered, we will be by your side until it is fully integrated with your manufacturing processes. If complications occur, we are available within 24 hours to get it right and have your systems up and running.

Rapid Prototyping. Rapid Production.

Unmatched Quality.

On-time Delivery.

Our longstanding experience in the automotive industry and our familiarity with its specialized materials and components allow us to expedite the production of your items from the drawing board to delivery. Our facilities can work with Acrylic capped ABS, TPO, Kydex, Royalite, and Boltaron, creating parts with best-in-field tolerances of +/- 0.001” – 0.010”. Global Thermoforming utilizes vacuum and pressure forming to create thick-gauge plastic automotive products tailored to your unique requirements.

Have an upcoming project?

Quick Lead Times

Thermoformed Automotive Equipment

Providing our automotive industry clients with fast turnaround and quick lead times is a specialty at Global Thermoforming. Our in-house team excels at rapid prototyping with custom tooling and remains available for consultation and problem-solving throughout the manufacturing process. Thick-gauge plastic thermoforming is ideal for automotive components, allowing our clients to manufacture large parts with lower tooling costs and tight assembly tolerances, using the best materials available.

What We Offer

Automotive Thermoforming

The automotive industry utilizes a diverse range of components and tools to build, maintain, and repair all kinds of vehicles. Their materials needs are just as varied. Global Thermoforming leads in providing thick-gauge thermoforming services to produce parts for companies such as Nissan, TRW, Local Motors, and Calsonic, as well as many others. Using specialized materials such as TPO, Kydex, Royalite, Boltaron, and Acrylic-capped ABS, our manufacturing facilities supply interior and exterior components.

Door Panels

Thermoformed interior door panels reduce vehicle weight, provide safety-compliant design features, and can be molded into complex shapes, as required. With attractive, durable, and easy-to-maintain surfaces, they’re ideal for all types of transportation.

Exterior Door Panels

Exterior door panels made from thermoformed plastic have become increasingly popular, replacing injection-molded plastic products, as well as aluminum and steel. Using TPO for these components provides integrated color that eliminates the need for painting.

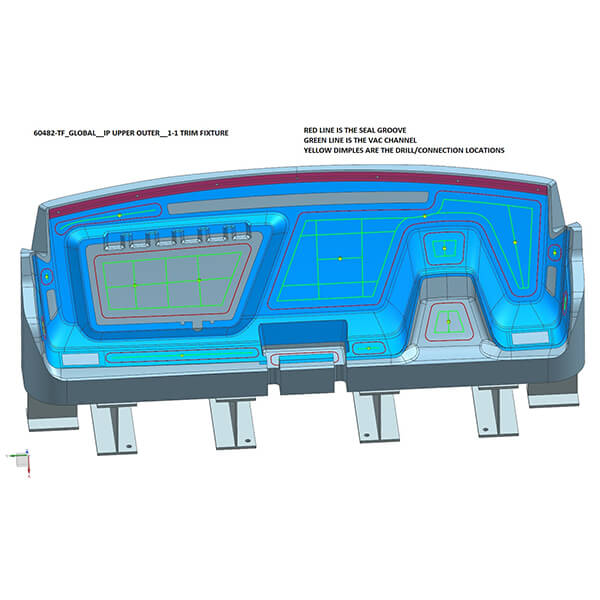

Instrument Panels

Vehicle instrument panels can require complicated designs, all while utilizing standardized and regulated materials. The items we manufacture are entirely customized to your specifications, using only the best materials. Thermoforming can create intricate, lightweight designs that accommodate automotive instrument components, airbags, integrated panel sections, and seamless single-panel pieces.

Glove Boxes

Glove boxes provide storage and often undergo much wear and tear. We manufacture durable pieces that are not only attractive and safe but easy to clean and maintain. Thermoforming can create a variety of surfaces to coordinate with any automotive interior.

Center Consoles

These essential automotive interior components must meet not only industry safety standards but stand up to everyday use. In addition, their designs can be more complicated than what meets the eye, as they must work with surrounding wiring and other interior features. We collaborate with our clients to produce surface details and custom elements that resist spills, tears, abrasions. The results are attractive, highly functional, light, and quiet in car interiors.

Custom Automotive PLASTICS MANUFACTURING

Automotive Thermoforming Gallery

CONTACT US

Automotive Thermoforming Inquiry

If you’re in the automotive industry and need to discuss your ideas for customized products using thermoforming, please get in touch. We’re experts with the types of materials and specialized designs you require for your project!

Copyright 2022 © Global Thermoforming | All Rights Reserved.

Site Designed and Developed by AVINTIV