How to Select a Thermoforming Company

Finding the right match for your projects can be simplified – if you know what to look for and the questions to ask. After over 30 years in the thermoforming industry, we not only have the answers – we know what you should be asking of your potential manufacturing partner.

Once you’re ready to select a thermoforming company for your product, the choices can be overwhelming. Each business has different specialties, unique processes, and their capabilities will vary. But which one is right for your current success and future growth?

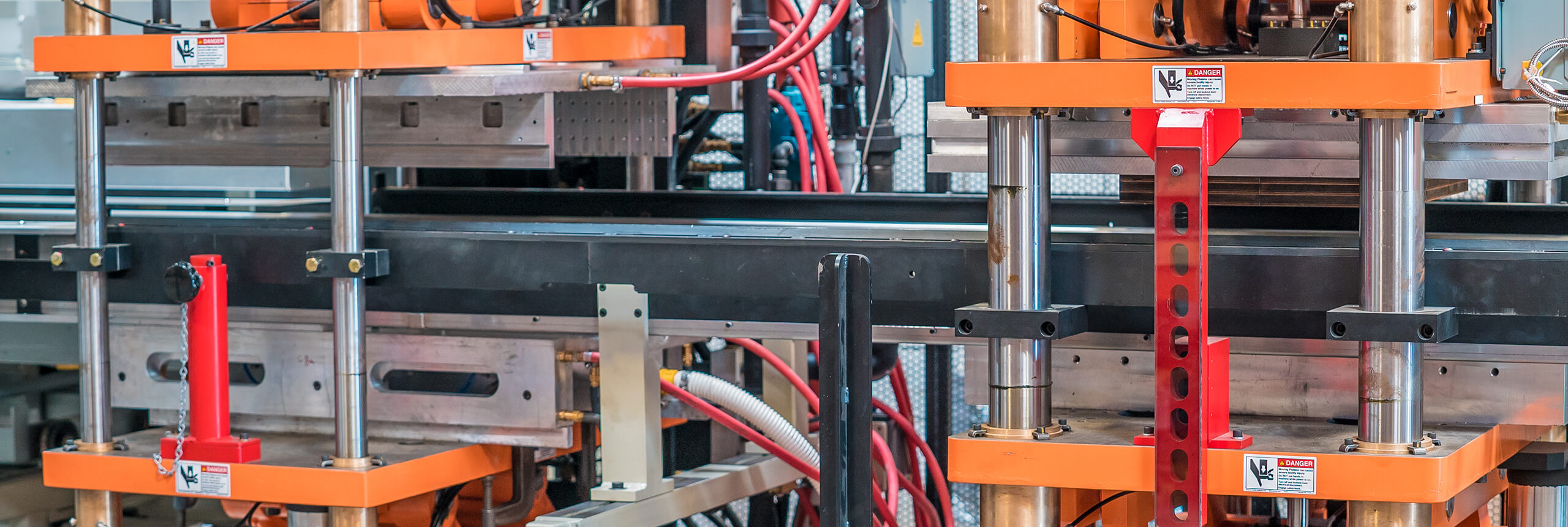

Equipment and Tooling Capabilities

Once the specifications for your product are completed, your thermoforming company must have the capabilities for fast, efficient production.

One example: size capacity can be a production deal-breaker. For larger components, ensure that your potential manufacturer has the machines to handle them. For example, at Global Thermoforming, we can form pieces up to 11’ x 7’ – matching your part to our array of equipment for the best results.

In-house manufacturing capacity is also essential. The ability to pressure form onsite reduces cycle times and allows companies like ours to deliver better pricing to our customers. Make sure to talk to thermoforming companies about their experience with thin or thick-gauge plastics, as well as their capabilities for close tolerance forming.

Materials Used

Every industry has its unique material requirements. As thermoforming companies expand, they may develop expertise in a limited range of materials. Ensure that the one you’re considering can work with the ones you need.

Global Thermoforming has a diverse portfolio of clients, including those in the Aerospace, Automotive, Packaging, Agricultural, and Medical Components areas. As a result, we work with a wide range of materials, including PVC, Acrylic, ABS, TPO, HDPE, and more – in both thick and thin gauges.

It’s hard to imagine that thermoformed plastics create everything from small, thin blister packaging pieces to large structural components used in vehicles and airplanes. Each thermoforming company will have its unique material capabilities.

Industry Specialization

Continuing from above, the right thermoforming company partner for your business should also have experience with your specific industry. When you’re selecting a candidate for your projects, discuss their specialized manufacturing fields. With the unique capacities of thermoforming, your choice must have experience with your type of components.

If you’re not acquainted with how diverse the thermoplastics field is, check out our previous blog on the subject! The process of molding plastics has created entirely new industries, as companies turn out everything from aircraft interior sections to automotive parts, handling trays, medical supplies, and food-handling items. Experience with specific industries can expedite the design, customization, and cycle time for a particular product.

Design and Customization

The right thermoforming company is invaluable as your company brings out new products. Here at Global Thermoforming, we are often part of the process, from design to specialization. Our in-house team can guide clients through design and prototyping, post-production machining, customizing, labeling, assembly, and more.

For maximum efficiency, quality thermoformers can offer these services in-house – saving you time and money.

Timelines

Let’s talk some more about production speeds. It’s always an advantage to minimize cycle times and get products out on the market; however, production speed is not solely influenced by the time spent in producing your thermoformed plastic components. Your company’s potential for innovation and growth also needs rapid prototyping for new items – done with precision and without sacrificing quality.

We’ve assisted our clients by producing prototype molds and parts in as little as 1-2 days. But, even our regular lead times are fast – just 2-4 weeks for prototypes, and 6-8 weeks for production. Our teams put this to the test recently with our response to the COVID 19 epidemic. We quickly shifted our production facilities to produce different types of face masks for medical professionals.

Scale of Orders/ Production Capacity

If you can’t get orders to your customers, your business won’t succeed. This simple concept should also apply to your thermoforming company. In addition to guaranteeing that they can produce your orders on time, they should also prepare for your growth.

We’re believers in our customers, and we want to be ready for their future success. From smaller orders to big production runs, Global Thermoforming is positioned to support clients as they innovate, fill larger orders, and increase their ordering capacity.

Your thermoforming company choices should be prepared to go as big as your success demands. Credentials are essential here: we stay ahead with our knowledge and training in the most current ISO 9001 practices, Lean Six Sigma techniques, and more.

Summary

Your company’s product is unique – and your choice of thermoforming companies should feel like a custom fit. Be prepared to talk about the nuts and bolts – or gauges and materials – of each aspect of the production process as you assess the candidates. Our extensive and versatile experience makes us the right choice for our current and future customers – we look forward to your call to discuss how we can help your company succeed and grow!

At Global Thermoforming, we stay involved through the entire process, and our ability to produce large parts with thin walls in a variety of shapes has led to the use of thermoforming in many diverse industries we serve. Including Aerospace Components, Medical Components, Bath & Shower Furnishings, Pools & Spas, Recreational, Vehicle Components, Sidings & Windows, Consumer Products, Appliances and Housewares, Automotive Components, Marine Components, Lawn & Garden, Agricultural Components, HVAC Components, Disposable Packaging. Contact us to learn more about Global Thermoforming.

Have an upcoming project?

Whatever your manufacturing needs may be, Global Thermoforming can put our engineering, design, and manufacturing expertise to work for you.