Learn more about Global Thermoforming

COVID-19 Manufacturing Initiatives

MENUMENU

- Our Company

- Gallery

- Services

- Industries

- Industries

- Thermoforming Industries

- Aerospace Thermoforming

- Agricultural Thermoforming

- Appliance Thermoforming

- Automotive Thermoforming

- Bath Showers Thermoforming

- Consumer Products Thermoforming

- HVAC Thermoforming

- Lawn & Garden Thermoforming

- Marine Thermoforming

- Medical Thermoforming

- Packaging Thermoforming

- Pool & Spa Thermoforming

- Recreational Vehicle Thermoforming

- Semiconductor Thermoforming

- Technology Thermoforming

- Window & Siding Thermoforming

- News

Thermoforming in Nashville, TN

Global Thermoforming offers a full range of concept development to production services for small-run to high-volume vacuum forming projects at both of our plants. Our Nashville, TN thermoforming plant specializes in thin-gauge thermoforming, thick-gauge thermoforming, close tolerance forming, and trimming capabilities.

Speed

We build our own thermoforming tools, thermoforming machines and extrude our own material, which means we can design and develop faster, fix production problems faster, and ensure you meet your deadlines.

Customization

We provide a broad array of plastic manufacturing capabilities. Whether your part calls for design, post-production machining, finishing, tooling manufacture, assembly or thermoformed packaging, we can handle all your needs on-site. We’ll make all the components!

Quality

Quality is the most important attribute of our vacuum forming company. We take great pride in delivering the best quality in the thermoforming industry. We are constantly striving to improve.

Customer Experience

Once your product is delivered, we will be by your side until it is fully integrated with your manufacturing processes. If complications occur, we are available within 24 hours to get it right and have your systems up and running.

EXPERIENCE YOU CAN TRUST.

1,000,000+ Parts Created

The Global Thermoforming brand infuses over 30 years of experience in vacuum forming and thermoformed packaging. Our thermoforming plant in Nashville, TN consistently produces high-quality and distinctive retail packaging, component parts, and POP displays for a variety of industries. We offer a full range of concept development to production services for small-run to high-volume vacuum forming projects. Our plant in Nashville, TN is known for our close tolerance forming and trimming capabilities. Although we are a privately-held company, we view our customers as shareholders. Your satisfaction is our primary focus.

Inquire about our thermoforming in Nashville, TN today.

QUALITY PRODUCTION

Nashville Thermoforming

Quality is Global Thermoforming’s most important attribute. We take pride in delivering the best quality thermoforming, vacuum forming, and thermoformed packaging in our industry. We are constantly striving to improve year over year. At Global Thermoforming, quality is everyone’s job, which is why we stay involved through the entire process. Once your thermoformed product is delivered, we will be by your side until it is fully integrated with your manufacturing processes.

What We Offer

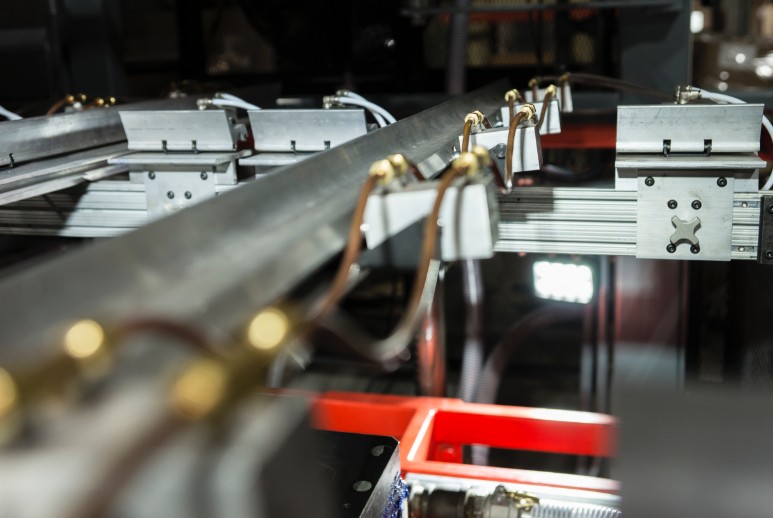

Nashville Thermoforming Equipment

Global Thermoforming is known for the quality, consistency and speed at which we’re able to produce for our customers. Our Nashville, TN plant has over eight thick gauge thermoforming machines, two thin gauge thermoforming machines, three CNC 5-axis and three 3-axis routers, two Haas CNC Mills, assembly room, and a variety of other secondary equipment. This level of space and equipment gives us incredible precision and speed as we produce thermoformed parts, components, and products faster and more precisely than ever.

8 Thick Gauge Thermoforming Machines

We specialize in thick gauge thermoforming with capabilities of forming up to 1” thick. With over ten thick gauge thermoforming machines at our Tempe, AZ plant, we’re able to form all types of thermoforming plastics.

2 Thin Gauge Thermoforming Machines

The thin-gauge plastics used in items such as food service clamshell containers, parts handling trays, and blister packaging are ideal for our In-Line Thermoforming machines. With two dedicated thin gauge thermoforming machines at our Nashville, TN plan, we’re able to get extremely detailed with your projects.

5 DMS 5-Axis CNC Routers

Our Thermwood 5-axis CNC Routers are specifically developed for three-dimensional machining and holding tight tolerances. A computer numerical control (CNC) router is a computer-controlled machine that can hold much tighter and more consistent tolerances than held by hand routers.

3 DMS 3-Axis CNC Routers

We know speed is critical, and router output capacity is vital. To maintain maximum output and minimum production times, we employ the latest technology and the best equipment. Our DMS 3-Axis CNC Router is ideal for configurability for a myriad of applications and projects that are capable of high production.

2 Haas CNC Mills

Our Haas CNC Mills machines are the industry standard for projects that are looking for a solution to small parts machining in a compact package while not sacrificing full-size features.

Assembly Room

Quality is at the forefront of everything we do at Global Thermoforming. That is why we have separate assembly rooms to add that extra layer of detail to every project that we work with you on.

CUSTOM THERMOFORMING

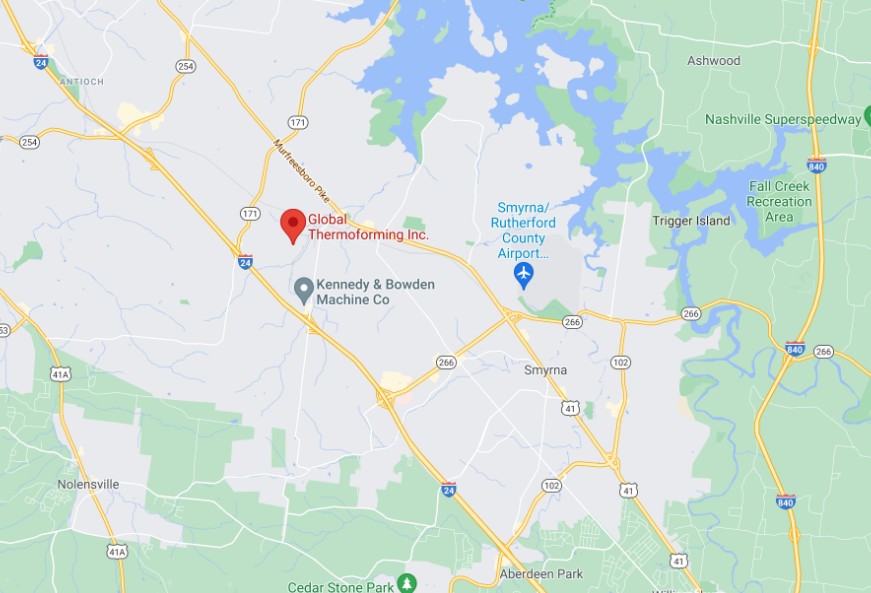

Nashville Manufacturing Plant

1631 CORPORATE PLACE

LAVERGNE, TN 37086

P: (615) 641-7000

F: (615) 641-7076

CONTACT US

Nashville Thermoforming Inquiry

Whether you’re a local or national business that has requirements for a small-run or high-volume project, contact us to see if we’d be a good fit to work with each other.

Copyright 2022 © Global Thermoforming | All Rights Reserved.

Site Designed and Developed by AVINTIV