Learn more about Global Thermoforming

COVID-19 Manufacturing Initiatives

MENUMENU

- Our Company

- Gallery

- Services

- Industries

- Industries

- Thermoforming Industries

- Aerospace Thermoforming

- Agricultural Thermoforming

- Appliance Thermoforming

- Automotive Thermoforming

- Bath Showers Thermoforming

- Consumer Products Thermoforming

- HVAC Thermoforming

- Lawn & Garden Thermoforming

- Marine Thermoforming

- Medical Thermoforming

- Packaging Thermoforming

- Pool & Spa Thermoforming

- Recreational Vehicle Thermoforming

- Semiconductor Thermoforming

- Technology Thermoforming

- Window & Siding Thermoforming

- News

HVAC Thermoforming

Global Thermoforming has the experience to provide our HVAC industry clients the highest quality and most durable products such as AC unit covers, drip pans and portable heating unit panels.

Speed

We build our own thermoforming tools, thermoforming machines and extrude our own material, which means we can design and develop faster, fix production problems faster, and ensure you meet your deadlines.

Customization

We provide a broad array of plastic manufacturing capabilities. Whether your part calls for design, post-production machining, finishing, tooling manufacture, assembly or thermoformed packaging, we can handle all your needs on-site. We’ll make all the components!

Quality

Quality is the most important attribute of our vacuum forming company. We take great pride in delivering the best quality in the thermoforming industry. We are constantly striving to improve.

Customer Experience

Once your product is delivered, we will be by your side until it is fully integrated with your manufacturing processes. If complications occur, we are available within 24 hours to get it right and have your systems up and running.

Solid Heating. Concise Cooling.

Heating and Cooling System Experts

If you are looking for the right fit for your next project, look to Global Thermoforming to provide you with pans, panels, and covers that outlast the competition. With the degree to which temperatures can vary, it is our understanding that each part of a heating and cooling system needs to be able to withstand the variance of pressure and temperature of its environment. Our team is ready to explore all of the various plastics that we keep in stock specifically for these types of projects with you to ensure your satisfaction with the end result.

Have an upcoming project?

On-time Delivery

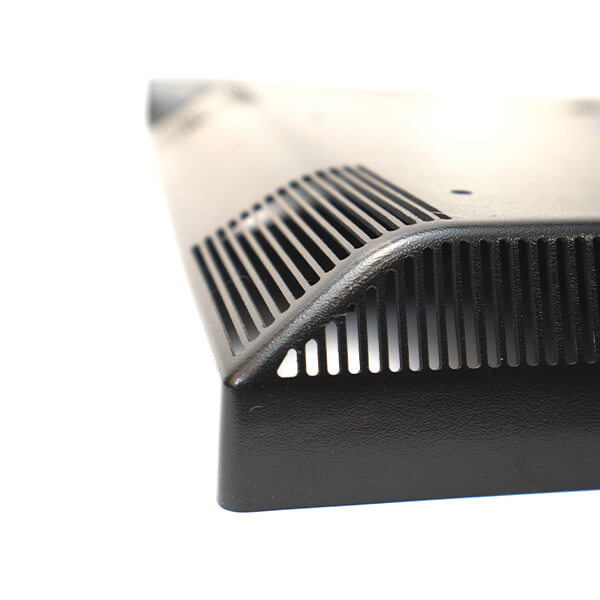

Thermoformed HVAC Equipment

Our vacuum forming process is efficient and built into stages you can follow with ease. Our team and machines work on schedules designed to make a greater impact on the results you are looking for. With access to on-site product development and the capacity to handle components from design to assembly and shopping, we eliminate delays and ensure each panel, part or plastic cover is manufactured to the tightest tolerances.

What We Offer

HVAC Thermoforming

The HVAC industry continues to serve a variety of companies and businesses in their heating and cooling needs. Our manufacturing processes at Global Thermoforming use large rotary thermoforming machines to complete the heavy gauge needs required to produce the covers and panels needed for HVAC equipment. Due to the years of experience, we have gained in this industry, we are able to partner with you to complete your orders promptly and efficiently.

Thermoformed Drip Trays

A Drip Tray, or Drip Pan, is commonly used in cooling systems, like swamp coolers, as a means for draining condensation from the unit. At Global, we are able to thermoform large quantities using the toughest plastics to ensure long-term durability.

Air Conditioning Unit Housing

Quick lead times and precisely produced parts are to be expected when we use our heavy gauge thermoforming expertise to create custom air conditioning covers. We have the right tools and machines, such as rotary thermoforming machines, to get the job done right for you.

Portable Air Conditioner Panels

Creating custom thermoformed panels for all types of air conditioning units, especially portable ones, is a straightforward process for us and we can assure you will find quality in each of our panels.

Portable Space Heater Panels

We supply the custom machined components and accessories that are a frequent requirement for aerospace clients. Aircraft interiors utilize a vast range of these items, such as ventilation ducts, wall and ceiling panels, and storage areas.

Custom HVAC Thermoforming

HVAC Thermoforming Gallery

CONTACT US

HVAC Thermoforming Inquiry

If you’re a part of the HVAC industry and would like to learn more about our HVAC thermoforming capabilities and how our team can help with challenging to design parts, faster turnaround times, and specialized materials experience, contact us today.

Copyright 2022 © Global Thermoforming | All Rights Reserved.

Site Designed and Developed by AVINTIV