Learn more about Global Thermoforming

COVID-19 Manufacturing Initiatives

MENUMENU

- Our Company

- Gallery

- Services

- Industries

- Industries

- Thermoforming Industries

- Aerospace Thermoforming

- Agricultural Thermoforming

- Appliance Thermoforming

- Automotive Thermoforming

- Bath Showers Thermoforming

- Consumer Products Thermoforming

- HVAC Thermoforming

- Lawn & Garden Thermoforming

- Marine Thermoforming

- Medical Thermoforming

- Packaging Thermoforming

- Pool & Spa Thermoforming

- Recreational Vehicle Thermoforming

- Semiconductor Thermoforming

- Technology Thermoforming

- Window & Siding Thermoforming

- News

Packaging Thermoforming

Global Thermoforming ensures that our packaging industry clients receive the best materials and tightest tolerances for products such as automotive trays, medical trays, electronic packaging, and more.

Speed

We build our own thermoforming tools, thermoforming machines and extrude our own material, which means we can design and develop faster, fix production problems faster, and ensure you meet your deadlines.

Customization

We provide a broad array of plastic manufacturing capabilities. Whether your part calls for design, post-production machining, finishing, tooling manufacture, assembly or thermoformed packaging, we can handle all your needs on-site. We’ll make all the components!

Quality

Quality is the most important attribute of our vacuum forming company. We take great pride in delivering the best quality in the thermoforming industry. We are constantly striving to improve.

Customer Experience

Once your product is delivered, we will be by your side until it is fully integrated with your manufacturing processes. If complications occur, we are available within 24 hours to get it right and have your systems up and running.

Trusted Expertise. Trusted Outcomes.

Thin-Gauge Plastics Thermoforming

Medical and automotive industries are just a couple of examples of industries that require solid, reliable thermoformed packaging for the various parts and components that are sold. Our thin-gauge thermoforming processes have gone through the stamp of quality assurance, as Global Thermoforming has received its ISO 9001:2015 certification. Protect your valuable products with the strength of our most durable plastics such as PET and more.

Have an upcoming project?

Quick Lead Times

Producing Packaging

Our experience with the packaging industry allows us to deliver on schedule. We build our own tools and secondary fixtures, as well as have an in-house engineering team, which saves valuable time in the thermoforming process. With access to on-site product development and the capacity to handle components from design to assembly and shopping, we eliminate delays and ensure each item is manufactured to the tightest tolerances.

What We Offer

Packaging Thermoforming

The diversity of components needed in the packaging industry requires experience and the capability to deal with a range of high-performance materials. Our team works with a wide range of plastics and thermoforming practices to be able to work on any type of project that comes our way. Below are some of the various packaging products we are able to manufacture.

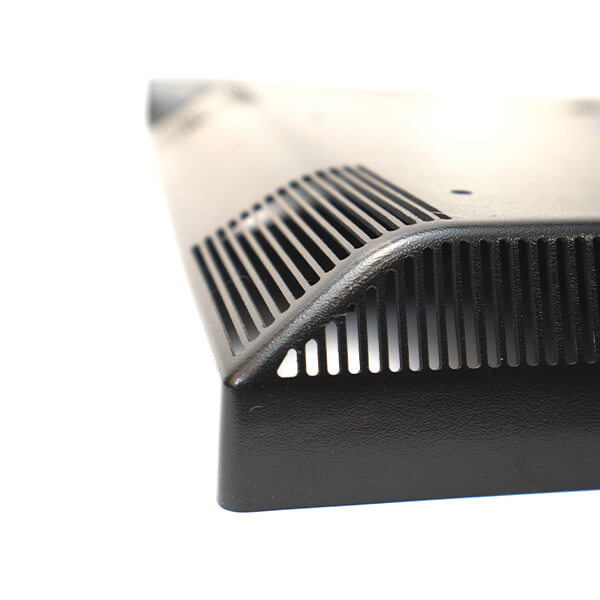

Electronic Component Packaging

From computer chips to products that have USBs, each has a common need: trusted, secure packaging. Our thin-gauge thermoforming processes create thin, easy to use and secure molds for products to be protected within and safely stored and transported.

Automotive Trays/Accessories and Dunnage Trays

Protect your industrial parts with dunnage trays that are thermoformed with the highest quality. We use thermoplastics like PET, PVC, and PP among others to produce automotive trays as well that perform and last for a long-time.

Medical Trays

Sanitation is critical when it comes to medical equipment such as medical trays. The need for plastics that are easy to reuse and maintain is key, and with our dedication to using durable thermoplastics, we are here to ensure the results will be to your satisfaction.

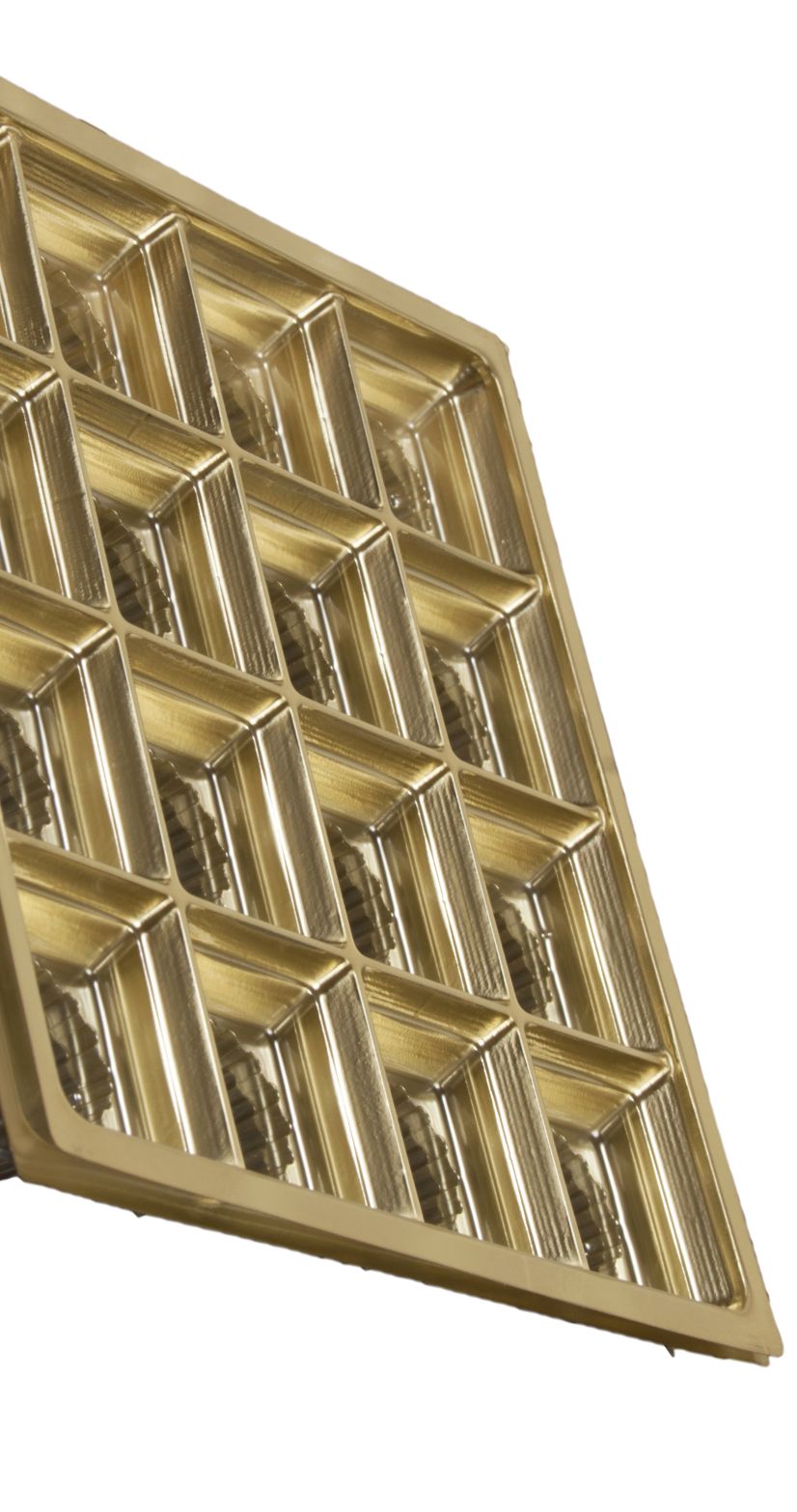

Semiconductor Trays

Resistance to the various environmental rigors that semiconductor trays go through is key. At Global Thermoforming, we use plastics that can stand up to the demands and pressures of heat, chemicals, and more. Our semiconductor trays are easy to work with and use while maintaining their shape and form.

POP Displays & Clamshells

POP Displays require unique features such as gloss finishes, and with the variety of acrylic plastics we offer in-house, we can customize your designs to fit the needs of today’s consumer markets.

Custom Packaging Thermoforming

Packaging Thermoforming Gallery

CONTACT US

Packaging Thermoforming Inquiry

If you’re a part of the packaging industry and would like to learn more about our thermoforming capabilities and how our team can help with challenging to design parts, faster turnaround times, and specialized materials experience, contact us today.

Copyright 2022 © Global Thermoforming | All Rights Reserved.

Site Designed and Developed by AVINTIV