Learn more about Global Thermoforming

COVID-19 Manufacturing Initiatives

MENUMENU

- Our Company

- Gallery

- Services

- Industries

- Industries

- Thermoforming Industries

- Aerospace Thermoforming

- Agricultural Thermoforming

- Appliance Thermoforming

- Automotive Thermoforming

- Bath Showers Thermoforming

- Consumer Products Thermoforming

- HVAC Thermoforming

- Lawn & Garden Thermoforming

- Marine Thermoforming

- Medical Thermoforming

- Packaging Thermoforming

- Pool & Spa Thermoforming

- Recreational Vehicle Thermoforming

- Semiconductor Thermoforming

- Technology Thermoforming

- Window & Siding Thermoforming

- News

Pool & Spa Thermoforming

Global Thermoforming ensures that our pools and spa industry clients receive the best materials and tightest tolerances for pool & spa thermoforming products such as hot tub shells, pools, and more.

Speed

We build our own thermoforming tools, thermoforming machines and extrude our own material, which means we can design and develop faster, fix production problems faster, and ensure you meet your deadlines.

Customization

We provide a broad array of plastic manufacturing capabilities. Whether your part calls for design, post-production machining, finishing, tooling manufacture, assembly or thermoformed packaging, we can handle all your needs on-site. We’ll make all the components!

Quality

Quality is the most important attribute of our vacuum forming company. We take great pride in delivering the best quality in the thermoforming industry. We are constantly striving to improve.

Customer Experience

Once your product is delivered, we will be by your side until it is fully integrated with your manufacturing processes. If complications occur, we are available within 24 hours to get it right and have your systems up and running.

Advanced Materials. Advanced Results.

Durability Reimagined

Global Thermoforming uses only the best materials when it comes to manufacturing for the pools and spa industry. Many times hot tubs require intense durability for temperature and wear, while at the same time requiring not only function but top-of-the-line form as well using modern aesthetics. Our vacuum forming and acrylic plastics have been tested and quality assured with our ISO 9001:2015 certification to ensure that you are satisfied with the results of our work, every time.

Have an upcoming project?

Expertise You Can Trust

Pools and Spa Equipment

With over 30 years of manufacturing experience, our team is able to quickly assess your needs and produce custom designs for large quantity orders. With this length of time that our team has worked in the industry, we’ve created a one-stop experience for our customers to ensure a smooth and seamless outcome, every time. From design to manufacturing, tooling, post-production services, we have it all ready for you to create the most impressive pools and spa equipment that you desire.

What We Offer

Pools and Spa Thermoforming

We have the tools and machines to manufacture large items such as hot tubs and pools that are even as large as 11’ x 7’ x 5’. We can assure you our capabilities are perfectly suited to produce durable items for long-term use. Below are a few of the items we manufacture within the pools and spa industries.

Hot Tubs

Heating acrylic sheets and using vacuum forming, we produce hot tub shells that are top of the line and inspected for perfection with every piece. We can produce hot tub shells within the realms of your desired colors and patterns, creating custom pieces clients can select upon their preference.

Packaging for Pool and Hot Tub parts

Global Thermoforming has expertise with both thick-gauge thermoforming as well as thin-gauge thermoforming, so when it comes to pools and spas, we can do both! The packaging needed for pools and hot tub parts requires a different set of machines and tools that we have on hand at both our Tempe and Nashville locations.

Pools up to 11’ x 7’ x 5’

Individual outdoor pools are becoming increasingly popular, and we have increased our capabilities in order to produce pools that are up to 11’ x 7’ x 5’ large. The thermoplastics we use are heat resistant, and UV-resistant to ensure long-lasting durability and protection for years to come.

Misting Machines for backyards

Our thermoforming capabilities can also execute more fine-detailed products such as misting machines for backyards. Water-repellant thermoplastics are used in combination with custom-designed molds to ensure that your product turns out exactly as envisioned.

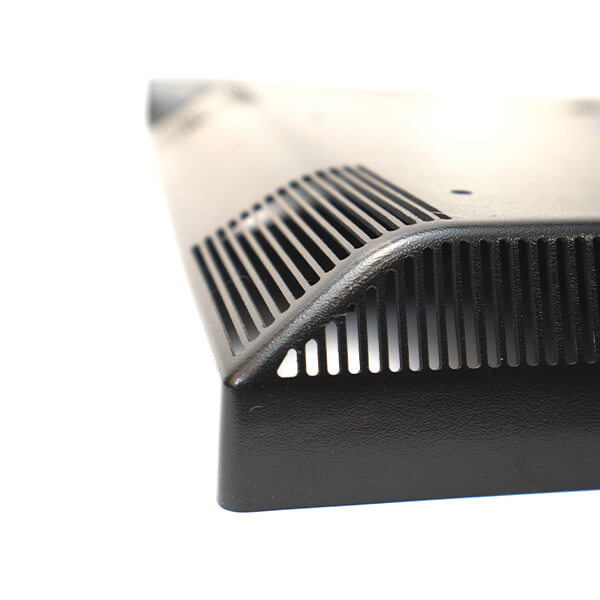

Electrical components for Pools/Hot Tubs

Panels and parts for pools and hot tub electrical components absolutely need some protection as well from environmental factors. Thermoformed materials will be the perfect fit to manufacture the covers and panels that surround electrical components so that there are no issues down the road when the hot tubs are in use.

Custom Pools and Spa Thermoforming

Pools and Spa Thermoforming Gallery

CONTACT US

Pools and Spa Thermoforming Inquiry

If you’re a part of the pools and spa industry and would like to learn more about our pools and spa thermoforming capabilities and how our team can help with challenging to design parts, faster turnaround times, and specialized materials experience, contact us today.

Copyright 2022 © Global Thermoforming | All Rights Reserved.

Site Designed and Developed by AVINTIV