Learn more about Global Thermoforming

COVID-19 Manufacturing Initiatives

MENUMENU

- Our Company

- Gallery

- Services

- Industries

- Industries

- Thermoforming Industries

- Aerospace Thermoforming

- Agricultural Thermoforming

- Appliance Thermoforming

- Automotive Thermoforming

- Bath Showers Thermoforming

- Consumer Products Thermoforming

- HVAC Thermoforming

- Lawn & Garden Thermoforming

- Marine Thermoforming

- Medical Thermoforming

- Packaging Thermoforming

- Pool & Spa Thermoforming

- Recreational Vehicle Thermoforming

- Semiconductor Thermoforming

- Technology Thermoforming

- Window & Siding Thermoforming

- News

Recreational Vehicle Thermoforming

Global Thermoforming has the experience to provide our recreational vehicle industry clients with the highest quality and most durable products such as panels for vehicle interiors, ceilings, exteriors, and more.

Speed

We build our own thermoforming tools, thermoforming machines and extrude our own material, which means we can design and develop faster, fix production problems faster, and ensure you meet your deadlines.

Customization

We provide a broad array of plastic manufacturing capabilities. Whether your part calls for design, post-production machining, finishing, tooling manufacture, assembly or thermoformed packaging, we can handle all your needs on-site. We’ll make all the components!

Quality

Quality is the most important attribute of our vacuum forming company. We take great pride in delivering the best quality in the thermoforming industry. We are constantly striving to improve.

Customer Experience

Once your product is delivered, we will be by your side until it is fully integrated with your manufacturing processes. If complications occur, we are available within 24 hours to get it right and have your systems up and running.

Rapid Prototyping. Rapid Results.

Custom Designed To Excel

Customization does not have to be a headache. At Global Thermoforming, we use our expertise to ensure smooth sailing through the steps of the thermoforming process. Our ISO 9001:2015 certification ensures the details will be prioritized to ensure a quality result you’re satisfied with. Our team has engineers on hand to discuss any questions and design inquiries with you to ensure we are the best match for your project.

Have an upcoming project?

Discover The Details

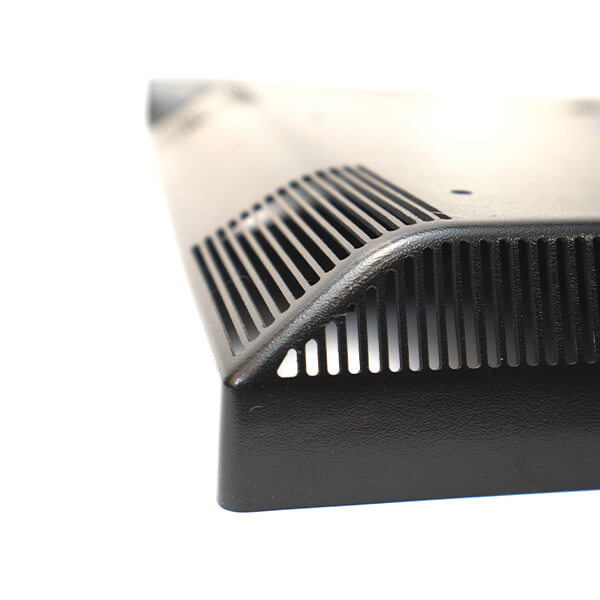

Thermoformed Recreational Vehicle Equipment

When it comes to the interiors of a recreational vehicle, there are a lot of intricacies that need to be accounted for in the parts’ designs. When you work with us, you get to work with engineers who look into the various details of your designs to ensure everything fits and goes together properly.

What We Offer

Recreational Vehicle Thermoforming

The Recreational Vehicle industry uses many different types of plastics for its parts. Some of these include ABS/polycarbonate alloys, polypropylene, PPE and SMA (styrene-maleic anhydride) depending on the type of feature being manufactured. Below are some of the types of products we produce within the recreational vehicle industry.

Instrument Panels

Every recreational vehicle will include an instrument panel. Nowadays, it is much more common to see a thermoplastic being used to produce this, as its durability and ease for production using vacuum forming creates a quality result.

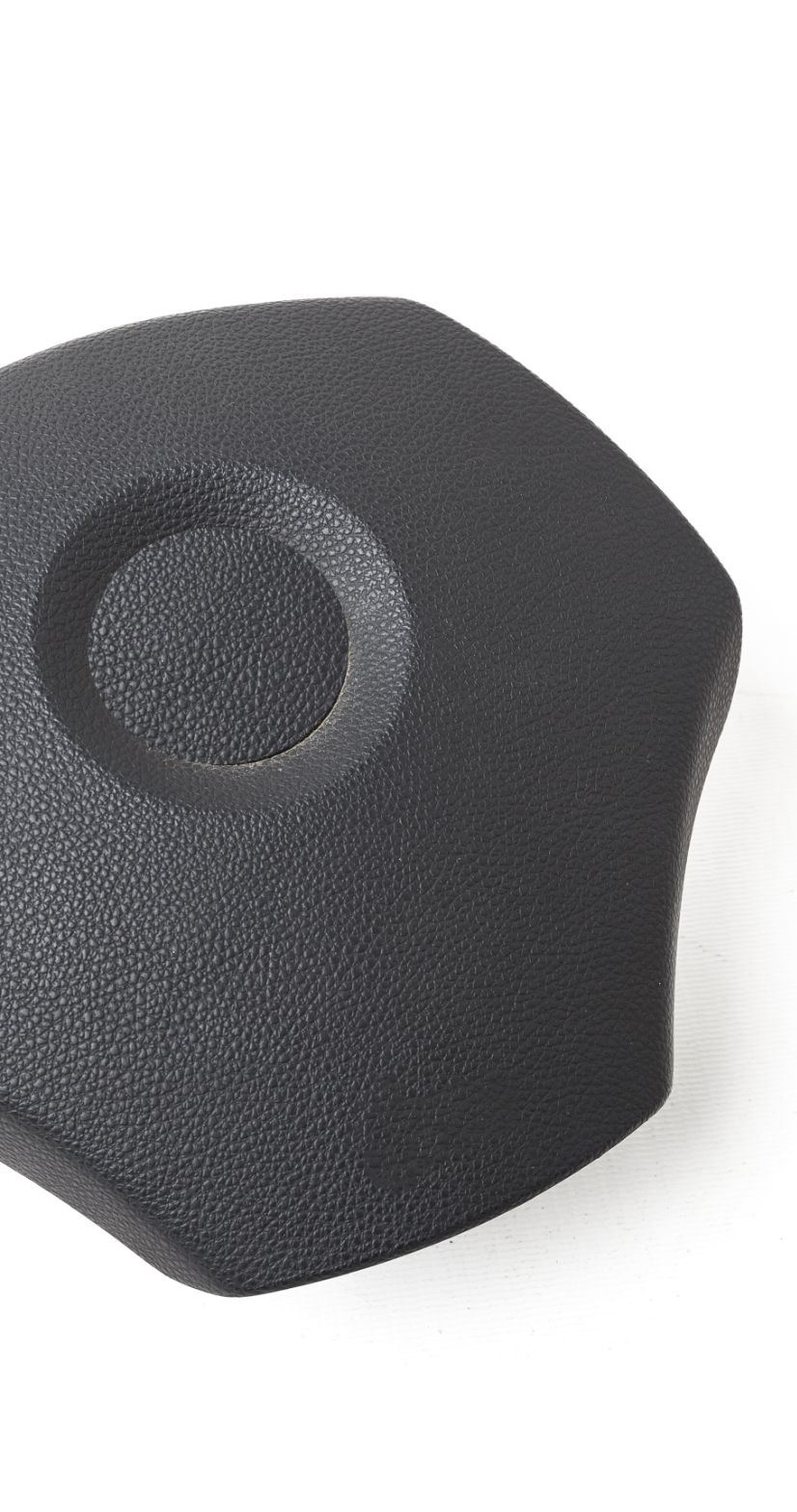

Interior Car Side Door Panels

Interior panels for cars are also easily fabricated using molds and thermoforming. Our team will work with you to decide on which styles work best for you.

Dashboards

Dashboards are usually manufactured using Polyvinyl Chloride, known as PVC, for its durability and benefit of being a flame-retardant material. Our team has years of experience in producing sleek, cutting-edge dashboards featured in many top-of-the-line vehicles.

Ceiling Panels

Ceiling panels, are one of the larger components we manufacture within the recreational vehicle industry. Our thermoforming machines are equipped to take on the heavy-duty nature of this type of product. We are detailed and inspect all parts to ensure proper fit and precise dimensions.

Exterior Panels

Exterior panels that are thermoformed need that extra touch for sleekness and environmental durability. Our variety of thermoplastics offers you options and choices in your designs so that you can stand out from the competition when everything is put together.

Custom Recreational Vehicle Thermoforming

Recreational Vehicle Thermoforming Gallery

CONTACT US

Recreational Vehicle Thermoforming Inquiry

If you’re a part of the recreational vehicle industry and would like to learn more about our recreational vehicle thermoforming capabilities and how our team can help with challenging to design parts, faster turnaround times, and specialized materials experience, contact us today.

Copyright 2022 © Global Thermoforming | All Rights Reserved.

Site Designed and Developed by AVINTIV