Learn more about Global Thermoforming

COVID-19 Manufacturing Initiatives

MENUMENU

- Our Company

- Gallery

- Services

- Industries

- Industries

- Thermoforming Industries

- Aerospace Thermoforming

- Agricultural Thermoforming

- Appliance Thermoforming

- Automotive Thermoforming

- Bath Showers Thermoforming

- Consumer Products Thermoforming

- HVAC Thermoforming

- Lawn & Garden Thermoforming

- Marine Thermoforming

- Medical Thermoforming

- Packaging Thermoforming

- Pool & Spa Thermoforming

- Recreational Vehicle Thermoforming

- Semiconductor Thermoforming

- Technology Thermoforming

- Window & Siding Thermoforming

- News

Thick Gauge Thermoforming

Custom Tooling and Thermoforming

Global Thermoforming as a leading heavy gauge thermoforming company that specializes in thick gauge thermoforming with capabilities of forming up to 1” thick. We’ve formed all types of thermoforming plastics in our industry and have helped our customers form their ideas into solutions they never dreamed of.

CLIENTS: BRIDGESTONE | GIBSON GUITARS | NISSAN | BOEING

Have an upcoming project?

Speed

We build our own thermoforming tools, thermoforming machines and extrude our own material, which means we can design and develop faster, fix production problems faster, and ensure you meet your deadlines.

Customization

We provide a broad array of plastic manufacturing capabilities. Whether your part calls for design, post-production machining, finishing, tooling manufacture, assembly or thermoformed packaging, we can handle all your needs on-site. We’ll make all the components!

Quality

Quality is the most important attribute of our vacuum forming company. We take great pride in delivering the best quality in the thermoforming industry. We are constantly striving to improve.

Customer Experience

Once your product is delivered, we will be by your side until it is fully integrated with your manufacturing processes. If complications occur, we are available within 24 hours to get it right and have your systems up and running.

THICK GAUGE THERMOFORMING

Custom Vacuum Formed Parts and Molds

Thick gauge thermoforming is a low-pressure process that transforms a flat sheet of plastic into a functional form or mold. The tools used in thick gauge or heavy-gauge thermoforming are much simpler and less expensive than other molding processes.

Examples of the custom thermoformed products we make are as follows:

- Pallets

Dunnage trays

Totes & Bins

Housings

Enclosures

Bezels

Guards

Radomes

Components

- Airport Luggage Totes

Medical Devices

Aerospace Interiors

Workout Equipment

Automotive Interior/Exterior

Fascias

Automotive Dunnage

Electronic Components

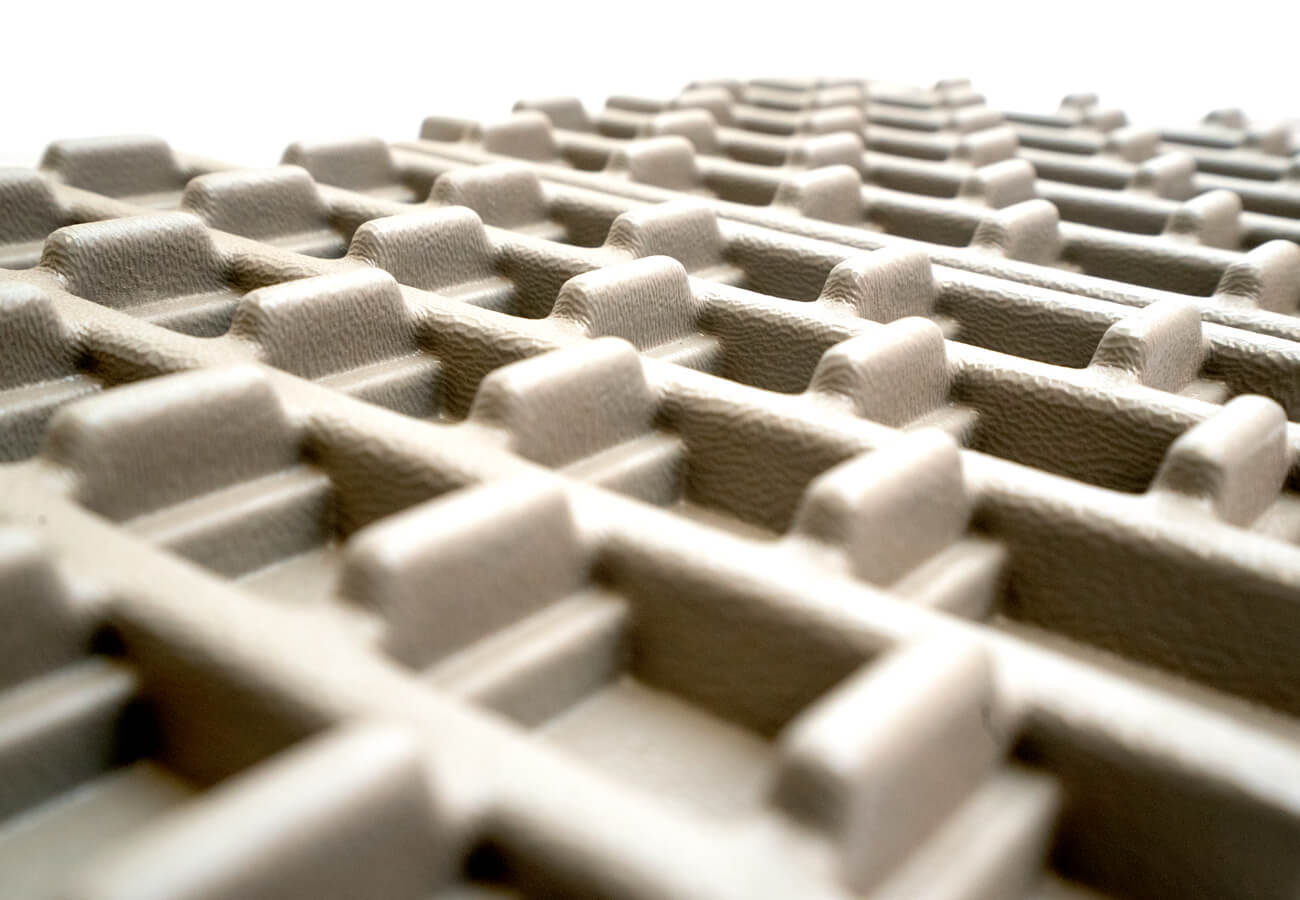

FINISHED PRODUCT

Thick Gauge Thermoforming

THICK

Aerospace Part

THICK

Automotive Dash Cover

THICK

Gibson Case Holder with Layered Materials

THICK

Fascia with Paint Finish and Accessories

BEST IN CLASS THICK GAUGE THERMOFORMING COMPANY

High Quality, Consistent Thick Gauge Thermoforming Molds

Of the many elements that contribute to a successful thermoforming operation, perhaps the most important is mold design. Well-designed molds made of the correct materials will promote consistent quality in the finished parts.

Conversely, the wrong materials employed in poorly designed molds are likely to compromise the work of even the most experienced processor.

The thermoforming process makes use of many types of molds. In fact, the low cost of thermoforming molds and the short lead times required for tooling can give this method great competitive advantages over other processing options.

Generally, only one side of the mold is needed to form parts from a heated sheet or film. This can be a male mold or a female mold, depending on the shape of the finished part, how the part will look (aesthetics), and the specific forming process used. The deeper the part being formed, the more critical the choice between male and female molds.

For shallow, low-profile parts, the reduction in wall thickness is typically minimal. Mold selection thus depends more on part appearance. If intricate mold details must be duplicated, the side of the sheet that touches the mold should be the one that becomes visible.

WE OFFER A VARIETY OF TOOLING SOLUTIONS

Types of Thick Gauge Thermoforming Molds

In-house capabilities feature multiple of the following vacuum forming machines.

Male vs Female Molds

A male mold is characterized by one or more raised elements (projections). The heated sheet is drawn over the projection(s) to form the part.

Male and female molds produce different wall thicknesses. Male molds typically produce parts formed with more thickness at the top. Parts formed using female molds show greater wall thickness around the edges.

Where deep draws are needed (up to 3:1 depth/diameter draw ratio), male molds are generally employed. A 3:1 depth/diameter ratio means that the thickness of an area of the part is just one-third of the original sheet thickness.

The depth/diameter draw ratio in female molds is typically limited to 2:1, unless the sheet is prestretched.

For irregularly or oddly shaped parts, the draw ratio is difficult to establish. Usually, it is calculated as the ratio of the maximum cavity depth to the minimum span across the edges of the unformed sheet.

Breakaways, Undercuts, and Inserts

Many thermoformed parts are produced with undercut sections. A popular method of forming a part with an undercut edge is to use a hinged undercut section.

Removable sections are often used. The operator removes the section from the formed part and returns it to the mold before the next part is formed. The undercut section can also be mechanically activated. When a slight undercut or reverse draft is necessary, stripper plates are often used. They are either spring loaded or mechanically operated.

When a design calls for an undercut to reinforce the part, an insert is often used. Inserts, which are typically made from metal, are positioned on the mold. During the forming process, the hot sheet wraps tightly around the insert.

Male and female molds produce different wall thicknesses. Male molds typically produce parts formed with more thickness at the top. Parts formed using female molds show greater wall thickness around the edges.

Where deep draws are needed (up to 3:1 depth/diameter draw ratio), male molds are generally employed. A 3:1 depth/diameter ratio means that the thickness of an area of the part is just one-third of the original sheet thickness.

The depth/diameter draw ratio in female molds is typically limited to 2:1, unless the sheet is prestretched.

For irregularly or oddly shaped parts, the draw ratio is difficult to establish. Usually, it is calculated as the ratio of the maximum cavity depth to the minimum span across the edges of the unformed sheet.

Matched Molds

A male mold is characterized by one or more raised elements (projections). The heated sheet is drawn over the projection(s) to form the part.

Male and female molds produce different wall thicknesses. Male molds typically produce parts formed with more thickness at the top. Parts formed using female molds show greater wall thickness around the edges.

Where deep draws are needed (up to 3:1 depth/diameter draw ratio), male molds are generally employed. A 3:1 depth/diameter ratio means that the thickness of an area of the part is just one-third of the original sheet thickness.

The depth/diameter draw ratio in female molds is typically limited to 2:1, unless the sheet is prestretched.

For irregularly or oddly shaped parts, the draw ratio is difficult to establish. Usually, it is calculated as the ratio of the maximum cavity depth to the minimum span across the edges of the unformed sheet.

Multiple Molds

Multiple molds form several parts in the same cycle.

A multiple-mold configuration generally has two decided advantages:

Greater output, and reduced trim scrap.

COMMONLY USED MATERIALS

In-House Mold Materials

Thermoforming uses relatively low temperatures and pressures. Because of this, a variety of materials can be used for making thermoforming molds. Molds can be made out of wood, plaster, plastic, aluminum, steel, sprayed metal, or layered metal. The choice of material depends on the number of production parts required and their quality.

Wood Molds

Molds made of well-dried hardwood are often used for low-production parts. Wood has a low thermal conductivity, and it won’t “chill” the sheet as it makes first contact with the mold. Wood molds, which must be preheated, are most commonly used for small production runs and are not advised for fast, repetitive forming in large volumes because of the inadequate heat rejection.

3D Printed Molds

Mold making with 3D printers has come a long way! We use 3D printing for functional prototypes, complex designs, & production components. Being able to print prototypes out of the same material as the final production part is invaluable.

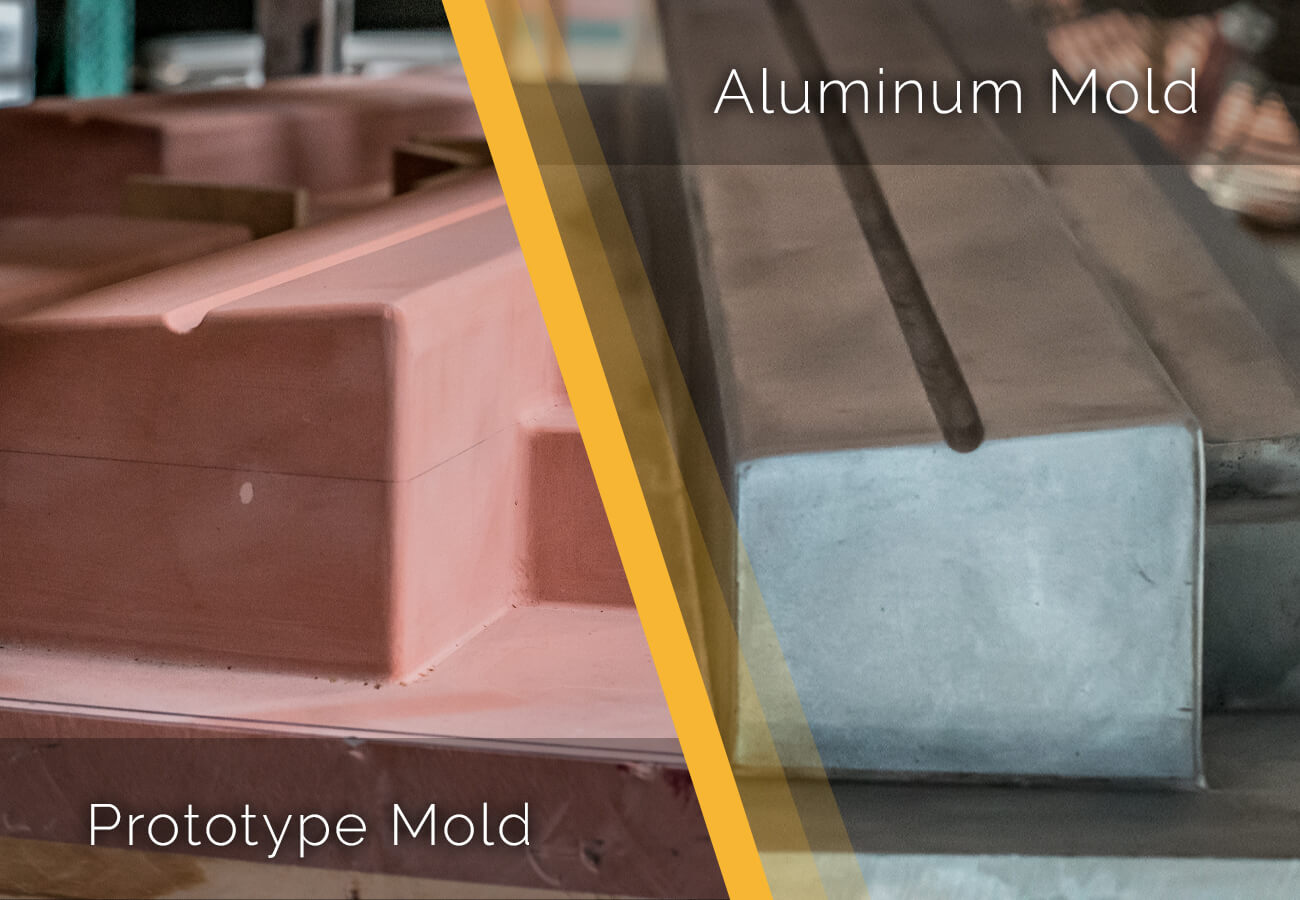

Epoxy / Polyurethane Prototype Molds

Epoxy and Polyurethane molds are used when speed, cost, and efficiency is of high importance. This is a much faster and relatively inexpensive way to create prototype molds in comparison to machined molds for production tooling. New epoxy products offer a much higher compression strength and heat resistance.

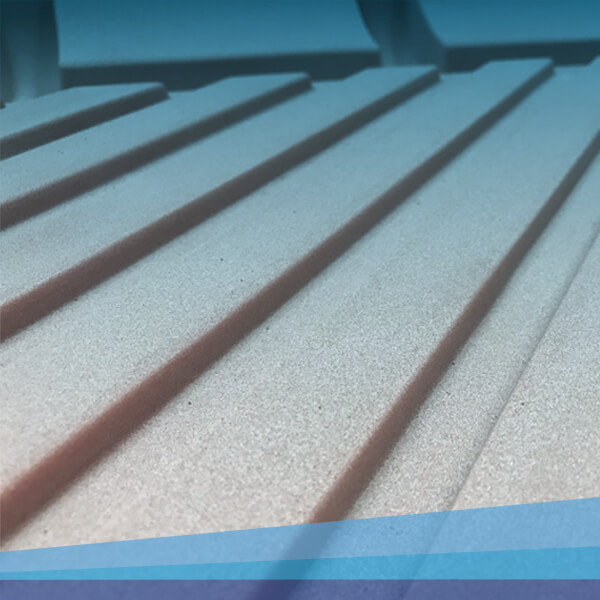

Aluminum Molds

For long production runs, cast or machined aluminum molds are usually chosen. They are prepared by casting or by layering and their surfaces can be textured or polished to a high gloss. Hard metallic coatings or applying polytetrafluoroethylene can improve the durability of the mold and the draping of the sheet. Coatings can also help maintain consistent sheet thickness. Aluminum conducts heat well. Heating and cooling are quickly done versus less conductive materials, allowing faster cycle time.

TYPES OF THERMOFORMING MACHINES

In-house Equipment and Machinery

In-house capabilities feature multiple of the following thermoforming machines.

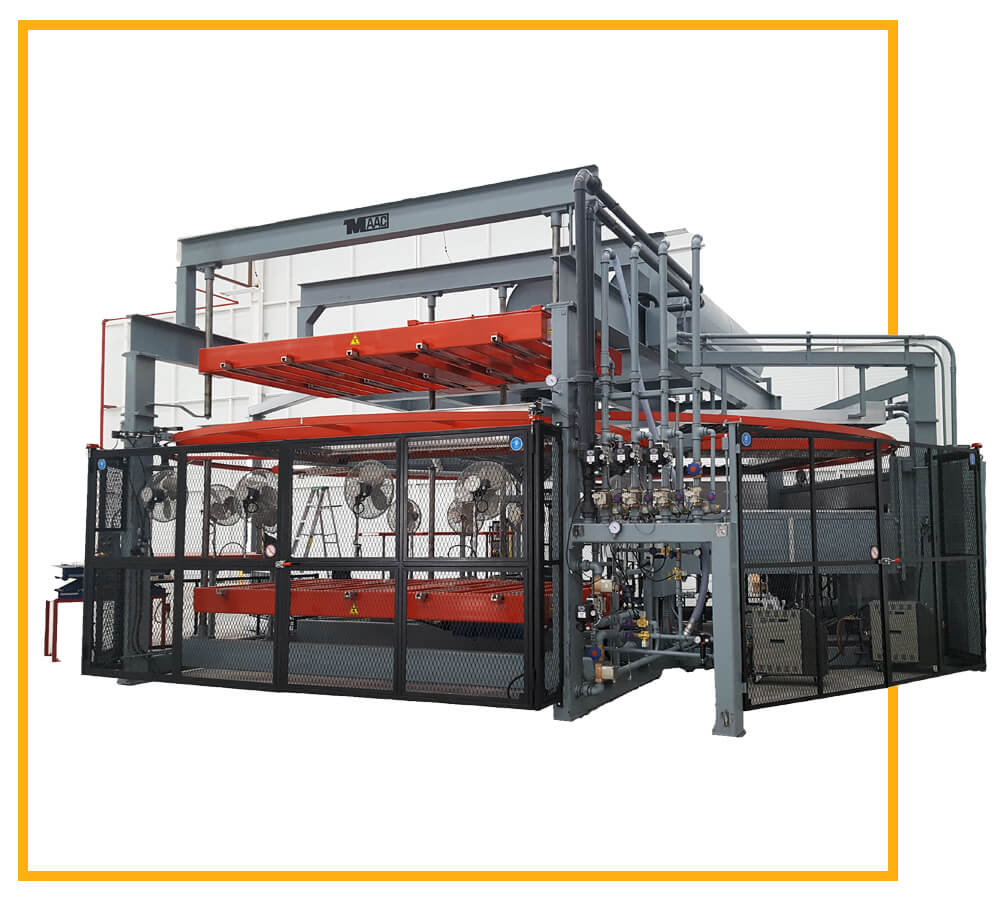

MAAC | FORMS UP TO 4'X5' - 11'X7'

Rotary Thermoforming Machine

Rotary thermoforming equipment can introduce even greater productivity in forming operations by arranging three or four workstations around a central area. Rotary machines with five stations are sometimes used but are far less common than three- and four-station machines. Only one mold and one forming station are needed on a rotary machine.

SENCORP 2500 | SENCORP 2500 ULTRA

In-line, Roll-fed Thermoforming Machine

A continuous web of material is fed from a roll and then clamped into a chain conveyor. The web moves through a bank of heaters, gets formed, and is moved out. The part is trimmed during cooling.

THERMWOOD | CUTTING UP TO 10’ X 5’

5 Axis CNC Routers

Our Thermwood 5-axis CNC Routers are specifically developed for three-dimensional machining and holding tight tolerances. A computer numerical control (CNC) router is a computer-controlled machine that can hold much tighter and more consistent tolerances than held by hand routers.

BROWN | SIZES RANGING FROM 1’X1’ - 11’X7’

Shuttle Thermoforming Machine

Here, the sheet is clamped into a moveable frame. The frame is located to the side of the stationary heaters. The sheet is then moved into the heater; when it reaches forming temperature, the sheet is moved back to the loading station and pressed into contact with the mold. The part is formed and cooled. The part is ejected after the mold is retracted.

Previous slide

Next slide

Global Thermoforming, Inc is a leader in the thermoforming industry that provides quality thermoforming, vacuum forming, clamshell, clamshell packaging, thin gauge thermoforming, thick gauge thermoforming, and a variety of other services to the entire United States. We have local thermoforming facilities in Tempe, AZ and Nashville, TN. Contact us today for all of your thermoforming needs.

Copyright 2022 © Global Thermoforming | All Rights Reserved.

Site Designed and Developed by AVINTIV