The Process Of Thermoforming

The Process of Thermoforming

Thermoforming is the process of taking a sheet of plastic material, heating it up until its pliable, and forming it to a three-dimensional shape, then trimming and finishing it into a usable product. In this article, we explain how the thermoforming process works.

Design

All our thermoforming projects start out with the design phase. Typically, thermoformed plastic is created as a part of a larger product. Often but not always, it’s the outer protective and aesthetic part for a larger part or product. Most thermoformed products start as a CAD model or engineered drawings. When customers come to us with a CAD file, more often than not our engineers work with the customer to refine the model into a shape that will work well with our plastics manufacturing process.

01

Thermoforming Mold & Materials Selection

Once the final designs are ready, we work with customers to select the right material for their project. ABS plastic is the most widely used plastic material for thermoforming, but there are quite a few other options that can be used for either aesthetic or functional reasons, including but not limited to fire-rated and high heat materials. All materials have unique physical properties and benefits, and thermoforming allows for a selection of colored and textured materials that can significantly enhance the appearance of the final product.

02

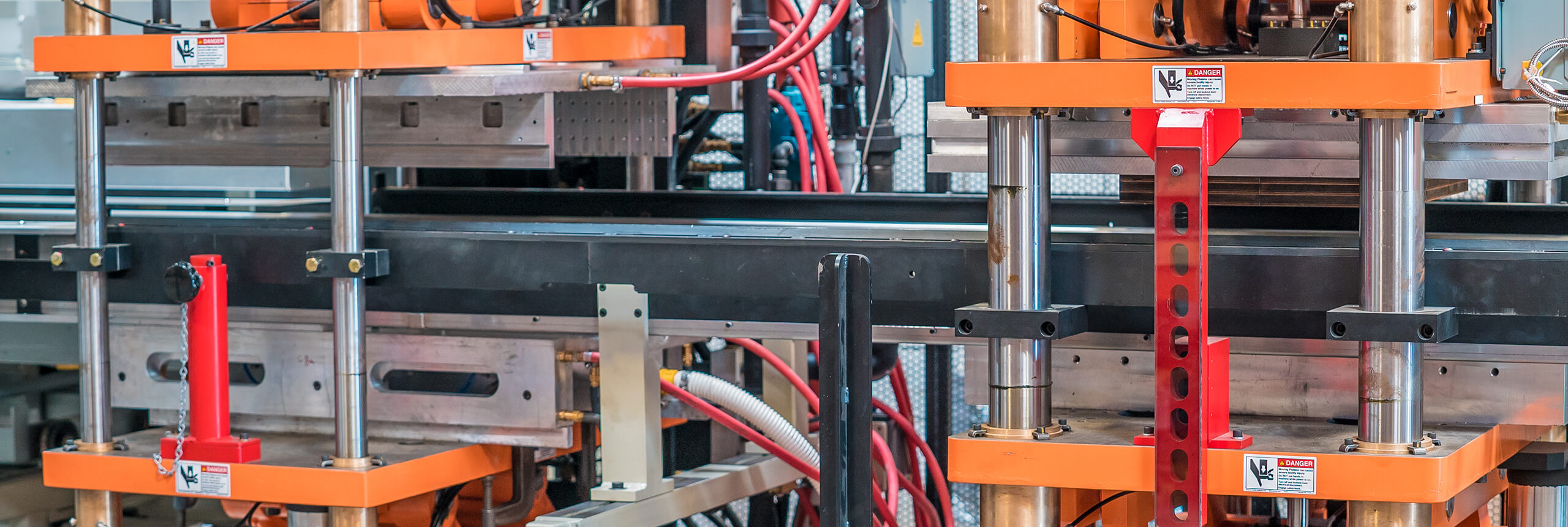

Thermoforming Tooling

After design and materials have been completed the next phase in the thermoforming process is the creation of the mold that the plastic will be heated to, called tooling. Our thermoforming process uses many different types of mold including aluminum molds. Depending on the size and complexity of the materials selected for the project, it’s often possible to combine several individual parts into a single mold, reducing tooling costs, material costs and production times. Global Thermoforming large scale thermoforming capabilities make this a popular option.

03

Vacuum Forming

Once materials are selected, the tooling has been developed, the next step is to form the plastic to the mold. Step 1 is to heat the plastic sheet to a pliable temperature, then shape it to the mold using vacuum pressure, air pressure or a combination of both. Once the material has formed to the mold, it’s cooled and removed from the mold, keeping its final shape. Since the final project cools against the mold surface under ambient temperatures, finished parts have zero residual stress.

04

CNC Routing & Trimming

Once a piece of plastic is thermoformed, there’s still some of the original material that needs to be trimmed. We use fully robotic 5 and 6-axis trimmers that can quickly cut complex and precise shapes, resulting in faster production times and more accurate and flexible cuts. Our robots also perform secondary operations such as cutouts, through holes and other features that require material removal.

05

Secondary Operations

After the custom plastic part/product has been thermoformed and trimmed, secondary services may need to be completed to finish the final part. We offer many secondary operations in-house, including painting, silk-screening, EMI/RFI shielding, the installation of inserts and other fastening devices and the assembly of hinges, handles, and other hardware. These services let us work as a single-source partner for many of our customers so that when they receive the completed part from Global Thermoforming, it’s fully ready to integrate with the rest of their manufacturing process.

06

Have an upcoming project?

Whatever your manufacturing needs may be, Global Thermoforming can put our engineering, design, and manufacturing expertise to work for you.