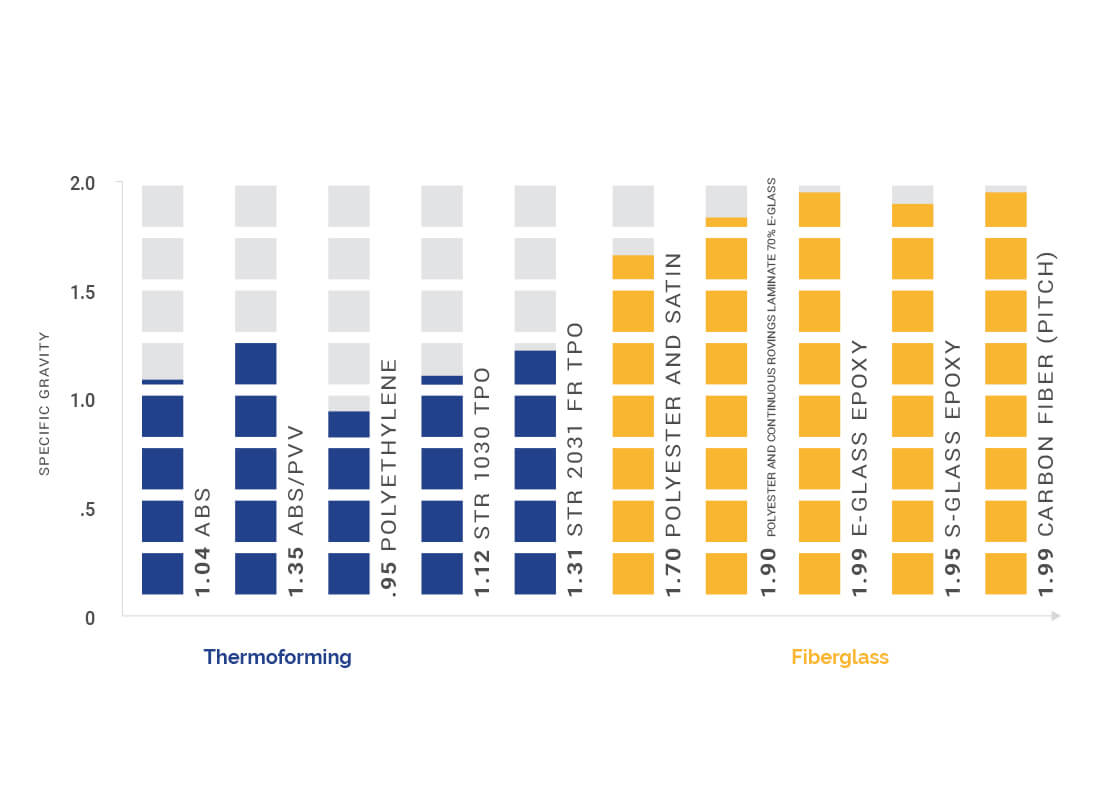

Which Plastic Materials Are Used In Thermoforming?

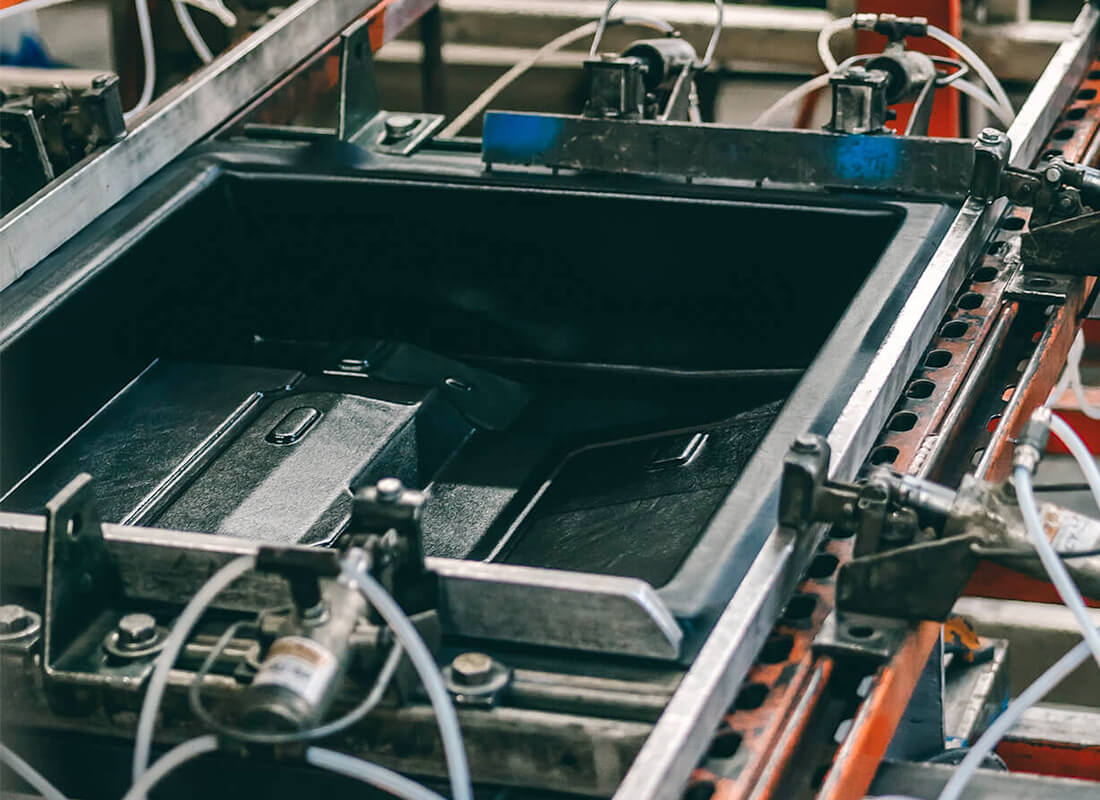

Thermoforming plastic sheets can use many types of material – but there are some key characteristics to consider. Factors like transparency, hardness, rigidity or flexibility, and impact strength help manufacturers select the right thermoplastic for each part. At Global Thermoforming, we work with a variety to ensure the products you receive are made from the best material match for your needs!