How Much Thermoformed Plastic Is Around You?

If you’ve been following our latest news, you know that Global Thermoforming has been adding new machines to our line-up, such as new shuttle thermoforming machines and 5-axis CNC routers. We’re always looking ahead to what’s possible within our industry – which made us wonder: Does everyone know all of the types of work we do? Do you know how much thermoformed plastic is around you?

With that in mind, we’d like to introduce just a few types of thermoformed plastic we fabricate. Our ability to produce large parts with thin walls in a variety of shapes is the reason our clients are so diverse. Here are 5 of the industries that we serve.

Thermoforming Industries and Work

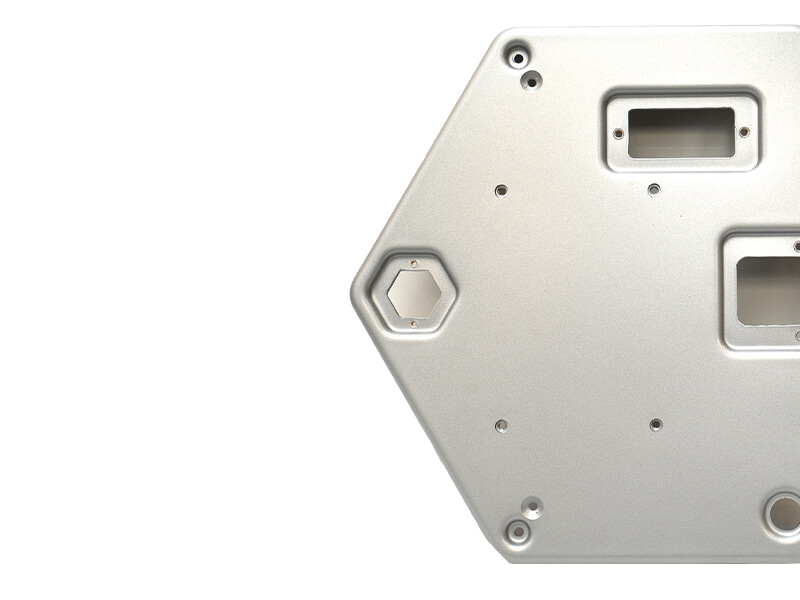

Aerospace/Aviation Interiors and Protection

The need for thermoplastic surfaces in airplane cabin interiors in aerospace thermoforming applications is a great fit with Global Thermoforming’s capabilities. Our new MAAC machines allow us to supply all types of pieces for plane interiors, where you might encounter them as a passenger. A sampling of products: seatbacks, sidewall panel sections, and much more.

You’re less likely to come up against another one of our products: radomes. These thick gauge plastic domes protect sensitive and delicate radar equipment and antennas while remaining transparent to radio waves.

Automotive Interiors and Shipping

Car parts and tools are yet another facet of the thermoforming automotive industry that we’re involved with. It’s not just car interiors that can benefit from the kind of thermoforming quality we deliver. Even though we handle items like panels and dashboards, other parts of the automotive manufacturing can benefit from thermoformed items. With the help of our Sencorp 2500, for example, companies can rely on us for shipping aids such as plastic shipping pallets and trays.

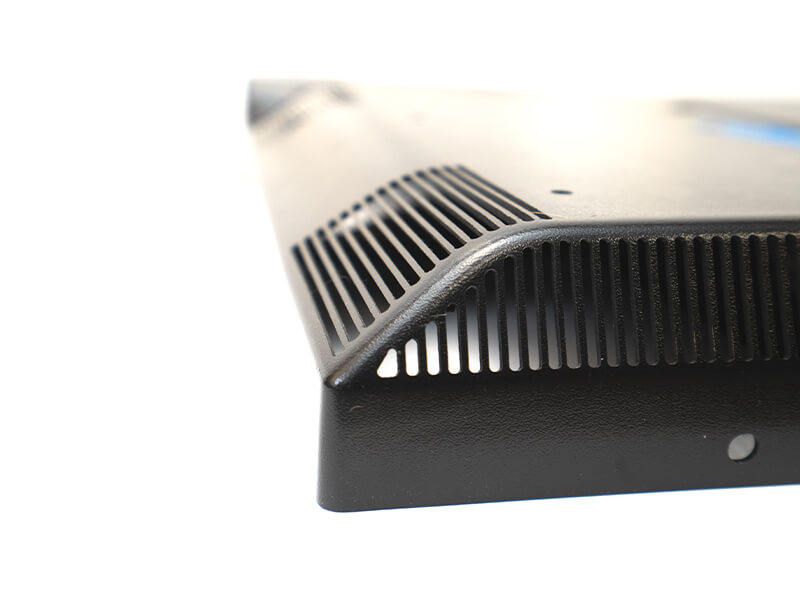

HVAC Protection

Thermoforming HVAC outdoor plastic housings is another niche Global Thermoforming fills. These heavy gauge pieces protect and preserve equipment in tough environments. Our MAAC units handle this type of pressure vacuum molding for our customers. These housings for HVAC installations and electrical equipment are durable, weatherproof protection, easily customized for even large units.

Mass Transit Components

For anyone who has utilized public transportation, the overall need for thermoforming quality might not be the first thought. However, thick plastic sheets and custom shapes make up all sorts of pieces that passengers use and engage with every day.

Thermoforming mass transit items such as seating and interior parts provides consistency, strength, and customizability to passenger areas. Also, thermoplastics allow operators to keep interiors updated and fresh as the years pass.

Another amazing offshoot of this industry are parts for autonomous vehicles. Much like the radomes produced for the aviation and aerospace industry, the cameras and equipment used for these machines need a protective shield. We can mold these covers into an aerodynamic shape that enhances vehicle operation.

Medical Applications

Thermoforming medical supplies and equipment have changed the healthcare environment – and it’s been a real game-changer. Staff and healthcare workers aren’t slowed down sterilizing equipment, and thermoformed pieces are cost-effective, chemical resistant, and light. Customizing textures and colors in thermoforming medical parts can also enhance the patient experience for healthcare providers.

Thermoformed Plastic In a Variety of Industries

Here’s a quick review of how thermoforming can be so versatile, and used in so many industries. When thermoformed plastics are formed over a mold with pressure or a vacuum, the results can be simple or quite complex. The nature of the manufacturing process allows us to produce pieces with high precision and high amounts of adjustability. We can produce everything from prototypes to large and complex pieces with speed and efficiency. For example, our latest acquisitions, the MAAC Comet Model C106S can make parts up to 6′ x 10′, and our 2019 Comet Model C64S can handle pieces up to 6′ x 4′.

Coupled with the type of precision routing that our CNC routers bring to our manufacturing facilities, Global Thermoforming is prepared to take on industries that work in virtually any field. In any application where issues such as aesthetics, customization, cost, and durability are important, thermoforming can be a superior option.

We’re always happy to hear about your ideas and talk about how we can put them into production for you. We’ve only covered a small portion of the industries we work with and the types of items we can manufacture. We welcome you to get in touch and find out more!

At Global Thermoforming, we stay involved through the entire process, and our ability to produce large parts with thin walls in a variety of shapes has led to the use of thermoforming in many diverse industries we serve. Including Aerospace Components, Medical Components, Bath & Shower Furnishings, Pools & Spas, Recreational, Vehicle Components, Sidings & Windows, Consumer Products, Appliances and Housewares, Automotive Components, Marine Components, Lawn & Garden, Agricultural Components, HVAC Components, Disposable Packaging. Contact us to learn more about Global Thermoforming.

Have an upcoming project?

Whatever your manufacturing needs may be, Global Thermoforming can put our engineering, design, and manufacturing expertise to work for you.